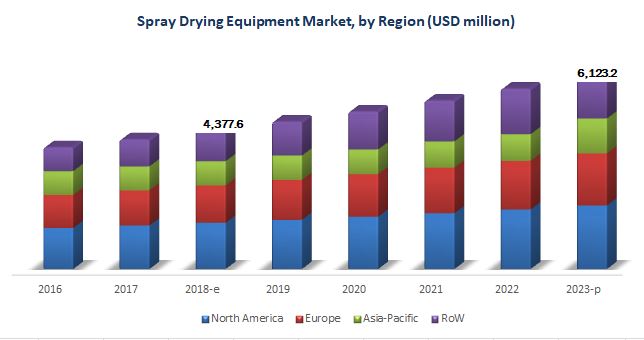

The report “Spray Drying Equipment Market by Type (Rotary Atomizer, Nozzle, Fluidized, Closed Loop, Centrifugal), Application (Food, Pharma, Chemical, Feed), Flow Type, Cycle Type, Drying Stage, and Region – Global Forecast to 2023″, The spray drying equipment market is estimated to be valued at USD 4.38 billion in 2018, and is projected to reach USD 6.12 billion by 2023, at a CAGR of 6.9% from 2018. Spray drying equipment have played an important role in the processing of food products, including dry soups, ready-to-eat (RTE) food, dry vegetables, coffee mixes, milk powders for lactose intolerants, and modified starches. Due to consumer preference for high-value convenience food products, a sudden demand in the market for spray drying equipment has been witnessed. The rise in popularity for functional food & beverages has also pushed the demand for this equipment in the food & beverage industry, which is expected to drive the growth of the global spray drying equipment market during the forecast period.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=229851536

Reduction in thermal damage caused to the product

The spray drying technology works by applying thermal energy, which acts on the product separating the liquid and turning it into fine granular or powder form. This type of process reduces the exposure time to high temperature, especially for heat-sensitive food products. As a result, spray dryers are preferred for drying fluid products. Vegetable and fruit juices are dried to their powder forms; this increases their shelf life and used as ingredients in other food products. Moreover, products such as these are sensitive toward thermal energy and can lose their nutrient value. Spray drying ensures that with controlled parameters, the nutrient values of the end product can be retained. Among all the industrial dryers, spray drying is widely used in the food, pharmaceutical, and related markets. Anyhydrobiotics such as probiotics are the most common food systems incorporated which retain the cell viability after processing. These are largely manufactured by spray drying considering the factors such as reduced thermal damage, low cost, energy, and throughput.

Misalignment in process parameters can affect the organoleptic properties

The spray drying technology has its own advantages, but if not correctly optimized, it can hamper the properties of the food products, such as taste and color. Parameters such as difference between the inflow and the outflow temperature, feed flow rate, residence time, temperature & design parameters of the drying chamber, heat & mass transfer, and drying kinetics of the air during production of food products; along with biology of bacteria; if not properly aligned, can result in imbalance in moisture composition in the final powder form. This kind of error would eventually dissuade smaller food manufacturers from installing spray dryers in their plants and opt for other drying methods. This can have a direct impact on the spray dryer manufacturing market.

Speak to Analyst: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=229851536

Asia Pacific is projected to be the fastest-growing region during the forecast period

The Asia Pacific region is projected to grow at the highest CAGR during the forecast period. The market in this region is mainly driven by the increasing demand for nutritional products among consumers. Increase in the demand for spray dryers for food encapsulation has been witnessed in the Asia Pacific region. The rising demand for spray drying equipment for dairy products, infant formula, and baby food is expected to drive the Asia Pacific spray during equipment market during the review period.

China was the largest country-wise market for spray drying equipment in the Asia Pacific region. It is one of the major hubs of spray dryer manufacturers and caters to the country’s top processing companies as well as to the export market. China is also one of the major markets for food and drug encapsulation in the world; the market here is projected to grow considerably in the next few years.

This report includes a study of business strategies, along with the product portfolios of leading companies such as GEA (Germany), SPX FLOW (US), Dedert Corporation (US), Buchi Labortechnik (Switzerland), European Spraydry Technologies (UK), Changzhou Lemar Drying Engineering Co. Ltd. (China), Shandong Tianli Drying Technology and Equipment (China), Acmefil (India), New AVM Systech (India), C. E. Rogers (US), Advanced Drying System (India), and Labplant (UK).

Media Contact

Company Name: MarketsandMarkets

Contact Person: Mr. Shelly Singh

Email: Send Email

Phone: 1-888-600-6441

Address:630 Dundee Road Suite 430

City: Northbrook

State: IL

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/spray-drying-equipment-market-229851536.html