Currently on the market, there are quite a few types of tarpaulin products, and different thicknesses are also available. Tarpaulin itself is a thicker cotton fabric or linen fabric. Although there are differences in thickness, the craftsmanship is essentially the same. In recent years, the shaping of the tarpaulin production process is progressing every day. Many people don’t know the difference between PE tarpaulin and PVC coated tarpaulin. Next, we will explain the difference between these two tarpaulins in essence.

PE tarpaulin

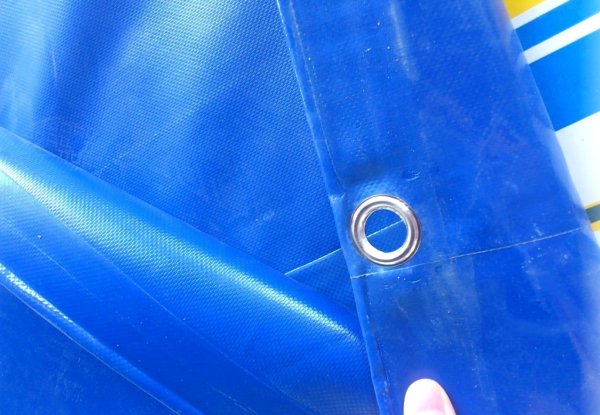

PVC tarpaulin is a high-strength polyester waterproof cloth coated with plastic, which uses high-strength polyester canvas as the base fabric, coated with polyvinyl chloride (PVC) paste resin and add a variety of chemical additives such as plasticizers, anti-fungal agents, anti-aging agents, antistatic agents, etc., plasticized at high temperature. It has the properties of waterproof, mildew, cold resistance, aging resistance, anti-static, etc.; and the breaking strength, elongation, and tear strength of this product are much better than traditional tarpaulins; The appearance of the product is gorgeous and colorful, which is pleasing to the eye. The surface is specially treated for anti-skid effect. It is an internationally popular waterproof canvas with a large width. When processing the finished product, it can reduce the seam and improve the quality. It can be heat-sealed and spliced to avoid the worry of water leakage in sewing needle holes. And products with different functions, colors and thicknesses can be produced according to user needs.

PVC tarpaulin is a polyester filament base fabric coated with PVC paste resin on both sides. Because it is a dipping process, one-time molding, there is PVC slurry in the gap of the cloth, so it has good waterproof performance. Its production process: polyester filament cloth-dipping coating-drying and setting-calendering and cooling-winding. Its production process: polyester filament cloth-dipping coating-drying and setting-calendering and cooling-winding. Now the tarpaulins on trucks, storage yards and other rainproof supplies are made of PVC tarpaulins. PVC material has good rain resistance, good durability, and anti-aging is far better than PE tarpaulin. Its waterproof effect is the most significant among all waterproof canvases. It is cold-proof and sun-proof. Most of them are used for long-term outdoor sheltering and rain-proofing, rain-proofing and wind-shielding canvas roller blinds for breeding, rain-proofing in coal yards, truck transportation, cargo ship covering and so on.

Most of them are used for long-time outdoor sheltering and rain protection, breeding rain and wind shelter canvas roller blinds, rain sheltering in coal yards, truck transportation, cargo ship covering.

Advantages: It has the properties of waterproof, mildew, cold resistance, aging resistance, and anti-static;

Disadvantages: PVC material will peel off for a long time;

PE: The chemical name is polyethylene. It is a semi-crystalline thermoplastic material, which is used to make PE tarpaulin.

So what are the characteristics of PE? Polyethylene is odorless, non-toxic, feels like wax, has excellent low temperature resistance, good water absorption, good electrical insulation performance, can be used normally at -70 to -100 degrees Celsius, and has good chemical stability. The production of PE tarpaulin generally uses HDPE (high-density polyethylene), which has a higher use temperature, hardness, mechanical strength, and good chemical resistance. Polyethylene is suitable for hollow blow molding, injection molding and extrusion of various products (hard), such as various containers, nets, and packing tapes, and can be used as cable coatings, pipes, profiles, sheets, etc.

The raw material of PE tarpaulin generally refers to colored striped cloth, which is coated with PE film on both sides of the woven cloth, and it also uses polypropylene woven cloth. The production process is: wire drawing—circular woven fabric—double-sided coating. The waterproof performance of this kind of tarpaulin is poor, and the waterproof performance is generally not guaranteed after using it once. The advantage is its light weight, clean and pollution-free, the disadvantage is that it is easy to wear. It is generally used for temporary storage of goods to prevent rain and dust, and is not suitable for long-term use in open environment.

Advantages: anti-sun, anti-freezing, anti-aging, anti-corrosion, light, easy to fold, durable;

Disadvantages: poor rain resistance

PE tarpaulin also has the characteristics of sun resistance, frost resistance, aging resistance, corrosion resistance, light weight, easy folding, and durability. The price is cheaper than PVC tarpaulin, but PE tarpaulin is not as durable as PVC, and the waterproof layer is also different. The PVC film used and the PE film used are both plastics. PE is soft in winter and PVC is harder, but PE is easy to wear, and PVC is a bit more wear-resistant. The waterproof layer is also different, one uses PVC film and the other uses PE film, both are plastic. PE is soft in winter, and PVC is harder, but PE is easy to wear, and PVC is a bit more wear-resistant.

The difference between PVC coating and PE coating

PVC coating: it can be applied thickly and relatively cheap. It is commonly used in conjunction with the calendering process and used for raincoats, bags, etc. The feel of PVC is rough, and there is also a kind of calendered PVC, which is harder.

PE coating: Polyethylene (PE) is non-toxic, low in cost and low in dosage.

Through the content we have introduced above, we can clearly understand the difference and respective characteristics of PVC coated tarpaulin and PE tarpaulin. Only when we understand these contents in detail, can we more accurately purchase products that suit ourselves.

Media Contact

Company Name: Jiaxing Juming Advance Cover Co., Ltd.

Email: Send Email

Phone: +86 0573 82829965

Address:Floor 2-2, Building 1, East Of Hengchang Tourism Supplies North Of Yufeng Road

City: Yuxin

Country: China

Website: https://jumtarps.com/