The laser cutting machine is the high-tech cutting machine. It plays an important role in modern industrial manufacturing with the advantages of environmental protection, high precision, high speed, high efficiency, and high quality. Despite all these advantages, higher processing results can be achieved in conformity with the properties of the cutting materials.

1. Structural steel

The application of oxygen in the cutting of structural steel brings better results. Cutting edges will oxidize slightly when oxygen is used as the auxiliary gas. Nitrogen gases are employed to perform high-pressure cutting for sheets in 4mm without the oxidization of cutting edges. The utilization of a special pole board for the laser and the application of oil to the surface of the workpiece during processing create better results for sheets in 10mm.

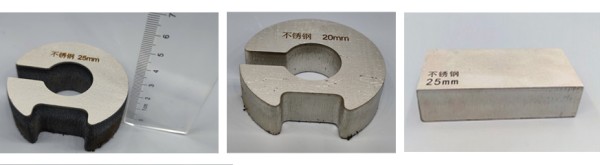

2. Stainless steel

Oxygen can be used in the cutting of stainless steel in case edge oxidation is acceptable. Post-processing is spared if nitrogen is employed for cutting stainless steel without oxidation and the generation of burs. Coating oil film on the surface of sheets can get a better perforation effect without reducing the processing quality.

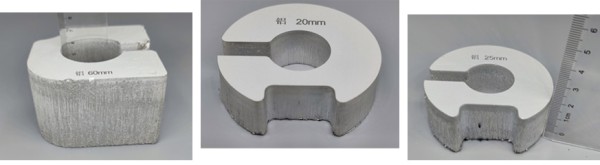

3. Aluminum

6mm aluminum with high reflectivity and thermal conductivity can be cut by the laser cutting machine. Cutting with nitrogen can generate smooth cutting finishes. Pure aluminum is very difficult to cut because of its high purity and can only be cut when the system is equipped with a “reflection absorption” device; otherwise, the reflection will destroy the optical components.

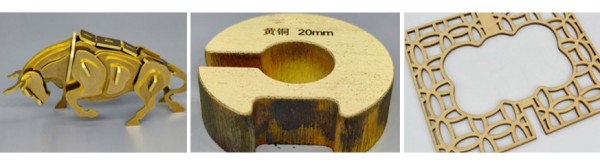

4. Copper and Brass

Both copper and brass have high reflectivity and good thermal conductivity. Brass in less than 1 mm can be cut with nitrogen; copper in less than 2 mm can be cut by the laser cutting machine and the processing gas must be oxygen. Copper and brass can only be cut if the system is equipped with a “reflection absorption” device; otherwise, the reflection will destroy the optical components.

5. Organics

There is a risk of firing for all organic cutting. Therefore, nitrogen and compressed gases can be used as the processing gases of organics.

In the operation of laser cutting machines, protective measures are important to avoid laser radiation harming the human body. Five major measures are as follows:

● Comply with environmental safety operating procedures. Strictly operate the laser cutting machine and start the laser in accordance with the operating procedures.

● Wear protective clothing and protective glasses as required. Typical protective equipment for laser cutting is laser protective goggles, which can be classified into reflective, absorptive, diffractive, and composite goggles according to protective principles. All of them can filter laser beams according to the laser wavelength of laser cutting machines to protect operators and they are also relatively safe and handy tools used in the operation of laser cutting machines.

● Do not process any materials without the clarification of whether they can be irradiated or heated by laser beams to avoid the potential danger from smoke and vapor. Operators must be trained to familiarize themselves with the structure and performance of the equipment and master the knowledge of the operating system.

● The operator shall not leave the post or entrust someone to be in charge when the equipment is on and shall stop or cut off the power switch if it is indeed necessary to leave.

● Put the fire extinguisher within handy reach and do not put place paper, cloth, or other flammable materials near the laser beam without any protection. Turn off the laser or light gate when processing terminates; do not place paper, cloth, or other flammable materials near the unprotected laser beam.

Media Contact

Company Name: LASERCHINA

Contact Person: Kevin

Email: Send Email

Phone: 86-10-64426993

Address:#22 Building, #13 Mintai Road Shunyi District

City: Beijing, 101300

Country: China

Website: https://www.laserchina.com/