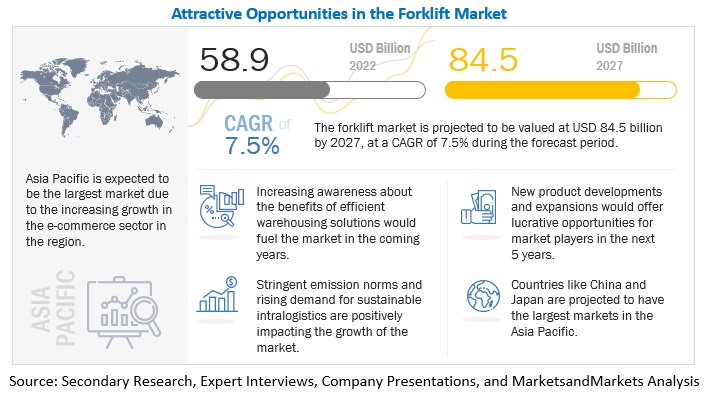

The forklift market is projected to grow from USD 58.9 billion in 2022 to USD 84.5 billion by 2027, at a CAGR of 7.5% for the same period. The base year for the report is 2021, and the forecast period is from 2022 to 2027. The market would witness growth owing to driving factors such as stringent emission norms, increasing need for sustainable material handling equipment for intralogistics operations, and the growing warehouse and logistics industries worldwide.

Market Dynamics

DRIVER: Increasing demand for lean and automated warehouses to increase operational efficiency

A lean warehouse reduces the consumption of resources without a reduction in productivity. For instance, a lean warehouse is optimized to avoid the unnecessary travel of empty forklifts, inappropriate material handling, storage practices, and bottlenecks of forklifts at the loading/unloading areas. Automation in warehouses is aided by automated forklifts, which can automatically travel and pick up/drop materials. The warehouse automation market grew from USD 9.95 billion in 2016 to USD 15.59 billion in 2021. One of the key reasons for this growth of the automated warehouses market is the development of autonomous forklifts. Autonomous forklift-driven warehouse automation is widely prevalent due to its minimal infrastructural requirements. According to Conveyco Technologies, automated forklifts with detection sensors can improve the operational efficiency of retail warehouses by 20%. The growing complexities of manufacturing and warehousing processes, labor constraints, and rising concerns for safety and health in production and storage facilities are driving the demand for flexible and cost-effective material handling solutions. In manufacturing plants, autonomous forklifts can perform repetitive tasks such as storing and retrieving inventory. In addition, the increasing need for efficient storage and retrieval processes in chemical and cold storage plants requires skilled labor to reduce spills and product damage. Thus, lean and automated warehouses greatly improve stability, productivity, and operational efficiency.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=2439790

OPPORTUNITY: Modular solutions to optimize customer productivity

Forklifts are designed for general material handling operations. But each customer’s requirements differ. For instance, customers who are not only the owner but also the operator of their forklifts expect a more spacious and luxurious cabin. Customers who steer more in their operations require a more conventional steering system. But mass-producing forklifts with such unique requirements is not a viable option. Manufacturers may even lose customers because they do not find their requirements. To overcome this, modular solutions can be offered to customers according to their requirements to optimize productivity. These modular products are expected to provide customers with enhanced flexibility in meeting their requirements. For instance, customers who require their forklifts to work for more shifts or even throughout the day can opt for an electric powertrain with a larger battery capacity. This reduces the total cost of ownership in the long run and increases productivity. Customers are benefited from the right features at the right cost and use them for the right applications. Hyster-Yale is one of the leading companies focusing on modular and scalable options covering both IC engines and electric forklifts. In 2020, the company announced that it would soon introduce such modular forklifts with the launch of a new range of counterbalanced trucks. These modular forklifts demand restructuring in the procurement and supply chain. When such modular requirements are observed from customers, their business/personal needs for a forklift can be observed. This direct engagement with customers also involves feedback from their existing forklifts. Manufacturers can use the feedback and requirements to develop their next forklift models.

CHALLENGE: Higher initial cost of electric forklifts

Conventional diesel and LPG forklifts greatly improve the productivity of users. However, due to increasing emission norms, high noise levels, and increasing fuel costs, the demand for an alternative mode of propulsion is increasing rapidly. As of now, electric forklifts are the most viable alternative mode of propulsion. However, the high initial cost of electric forklifts over conventional forklifts hinders the growth of the electric forklift market. Electric forklifts are around 20% more expensive compared to conventional IC forklifts. Though their ROI is better, it is difficult for SMEs to procure electric forklifts. Also, if the productive work hours in SMEs are relatively less, the ROI on electric forklifts is further extended. This makes it less feasible for them to opt for electric forklifts over conventional forklifts, even if they prefer to be sustainable. Also, the initial cost of autonomous forklifts is higher than electric forklifts. This makes them inaccessible to small and medium-sized companies.

Asia is projected to be the largest market by 2027

The Asia Pacific region is considered one of the world’s largest automobile and industrial production and manufacturing hubs. Many of the leading countries in this region are emerging in various industries and are actively incorporating material handling equipment in their operations. China has emerged as a manufacturing hub, and according to the National Bureau of Statistics, the average industrial production index growth rate of China was nearly 10.9% in December 2022. Huge domestic demand for products and services and significant business growth opportunities have led to the establishment of manufacturing and warehousing units for various industries, such as automotive, metals and heavy machinery, and semiconductors and electronics, in the region. This offers an attractive growth opportunity for the forklift market in the Asia Pacific region. In addition to the increase in population, factors such as increasing GDP, infrastructure investments, rising per capita income, and growing inclination toward comfort and leisure have created more opportunities for forklifts in the Asia Pacific region.

Key Market Players & Start-ups

The forklift market is led by globally established players such as Toyota Industries Corporation (Japan), KION Group AG (Germany), Mitsubishi Logisnext Co. Ltd. (Japan), Jungheinrich AG (Germany), and Hyster-Yale Materials Handling (US). These companies adopted expansion strategies and undertook collaborations, partnerships, and mergers & acquisitions to gain traction in the high-growth market.

Request Free Sample Report @ https://www.marketsandmarkets.com/requestsampleNew.asp?id=2439790

Media Contact

Company Name: MarketsandMarkets™ Research Private Ltd.

Contact Person: Mr. Aashish Mehra

Email: Send Email

Phone: 18886006441

Address:630 Dundee Road Suite 430

City: Northbrook

State: IL 60062

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/forklift-market-2439790.html