In 2023, our company exported a permanent magnet direct-drive electric drum to Laos and dispatch relevant service personnel to perform installation, commissioning and related training on site. Now it has been successfully delivered, and the permanent magnet roller can be shipped to sea.

The belt conveyor is a key equipment for conveying materials. The transmission device is the driving component of the belt conveyor, and its characteristics directly affect the stability and energy consumption of the belt conveyor. The traditional drive mode of the belt conveyor is traditional asynchronous motor + reducer + roller drive, which results in the system having problems such as long mechanical transmission chain, low efficiency, complex mechanism, and heavy operation and maintenance workload. Therefore, improving the operational reliability, efficiency and power factor of the belt conveyor itself is one direction of motor design. Using variable frequency permanent magnet direct-drive electric drum to shorten the transmission chain, reduce fault points, and improve transmission efficiency is one of the important means to transform the belt conveyor.

Background of the project

New 750,000 tons/year belt conveyor project

Location: Khammuan Province, Laos

Name of conveyed material: Carnallite raw ore

Material characteristics: Moisture content 5%, non-toxic, non-static, slightly corrosive (chloride ion corrosion), the main ingredients are carnallite, potassium chloride, sodium chloride, the ore is more likely to absorb moisture and cause salt blockage

Altitude: 141~145 m;

Atmospheric pressure: 0.IMPa:

Climatic conditions: The area has a tropical and subtropical monsoon climate. The rainy season is from May to October, and the dry season is from November to April of the following year;

Annual average temperature: 26℃, maximum temperature: 42.5℃, minimum temperature: 3℃

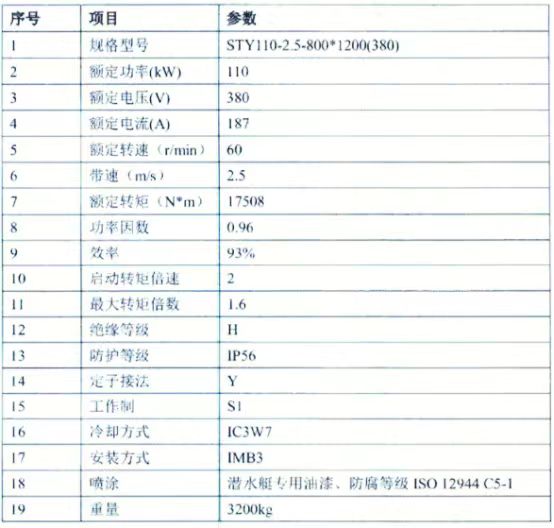

Our company has developed a plan in strict accordance with the process conditions, equipment technical requirements and related standards.

After careful production and testing, the products were packaged and shipped to Laos. At the same time, the company’s technical service personnel and sales engineers also went to the site.

The application of permanent magnet mototorized pulley greatly ensures the efficiency, performance and stability of the customer’s conveyor operation. After the delivery was completed, the customer spoke highly of the use effect of permanent magnet motorized pulley and the professionalism of the technical service staff.

So many people will wonder what exactly is a permanent magnet conveyor pulley? What are the advantages of permanent magnet conveyor pulley? The following will introduce them one by one to you.

What is permanent magnet conveyor pulley?

The permanent magnet conveyor pulley takes advantage of the characteristics of the permanent magnet motor that can be designed into a multi-pole structure. The drive roller of the conveyor is integrated with the permanent magnet motor and is designed as a driving device for the outer rotor and inner stator. The permanent magnet electric conveyor pulley directly drives the belt without any intermediate transmission links.

Why choose permanent magnet motorized pulley?

1: Energy saving

The unique rotor magnetic circuit design achieves perfect sinusoidal field strength distribution, greatly reducing the generation of harmonics. The efficiency is high. At low load, the efficiency can still reach 90%. There is no need to consider power redundancy when selecting the motor. In addition, compared with the original system, the improved driving method eliminates mechanical transmission devices such as reduction boxes. The permanent magnet electric roller can directly meet the needs of the belt conveyor system and achieve low-speed, high-torque transmission requirements.

2: Low loss

The rotor does not produce induced current, and there is no copper loss or iron loss.

3: High power density

The motor is small in size and light in weight.

4: Maintenance-free

The simplified electric drum drive system is basically “maintenance-free”, which greatly reduces the downtime caused by equipment maintenance and reduces the losses caused by downtime. There is basically no need to increase maintenance costs during use, achieving “once investment, lifelong benefits”.

5: Closed-loop vector control

Closed-loop vector control can be used to achieve power balance for multi-machine drives, reduce belt wear and extend the service life of the conveyor.

In modern mine coal production enterprises, transportation is a very important link, and its transportation capacity directly affects output. Currently, enterprises mainly rely on belt conveyors and rail mine cars to transport materials. Because belt conveyors have the advantages of large transportation capacity, high continuous operation efficiency and reliable operation, they have become the most commonly used transportation method by coal mining enterprises.

As a company specializing in R&D, production and manufacturing of permanent magnet motors, Anhui Mingteng Permanent-Magnetic Machinery & Electrical Equipment Co., Ltd. relies on 17 years of experience to provide high-quality drive solutions to more than 300 companies, and continues to optimize permanent magnet motors and Drum products (here is the link to drum products), successfully solving the difficulties and pain points of various industrial and mining enterprises in the drive system. In the future, we also hope that more and more people will learn about permanent magnet direct drive rollers and use permanent magnet conveyor pulleys.

Media Contact

Company Name: Anhui Mingteng Permanent-Magnetic Machinery & Electrical Equipment Co., Ltd.

Email: Send Email

Country: China

Website: https://www.mingtengmotor.com/