3D Concrete Printing Industry

Summary:

-

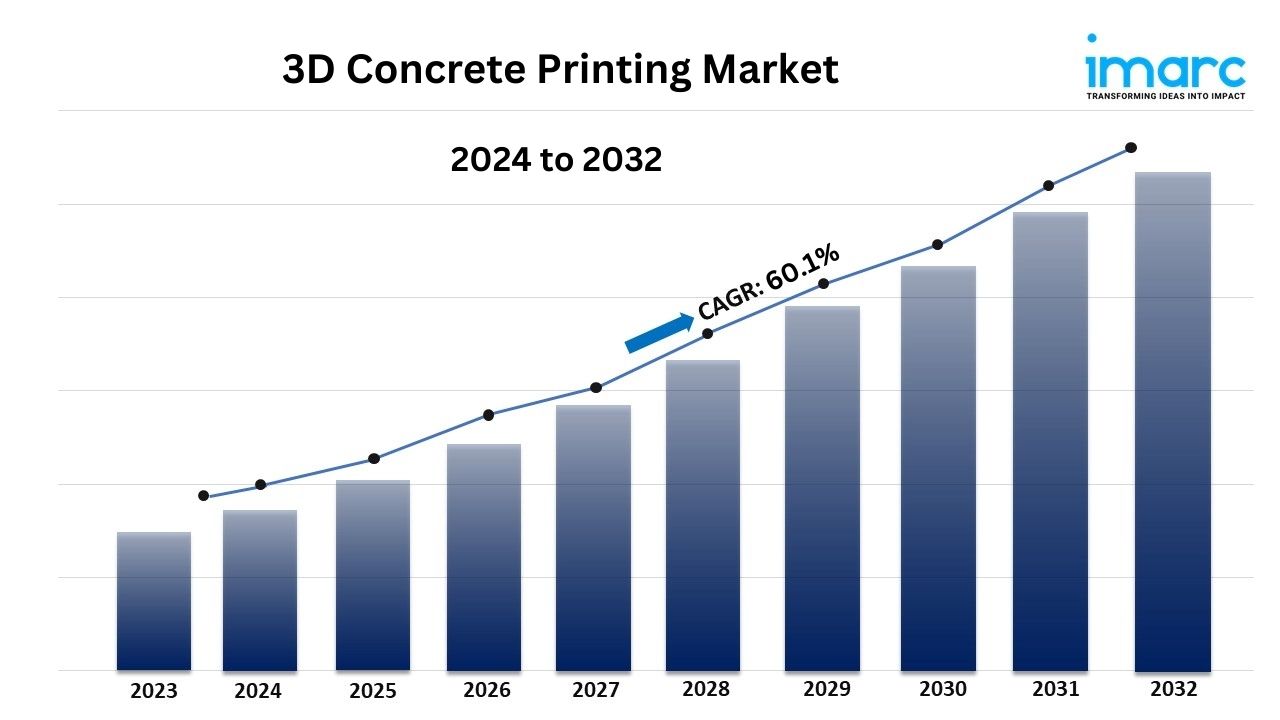

The global 3D concrete printing market size reached USD 2,141.5 Million in 2023.

-

The market is expected to reach USD 158,150.9 Million by 2032, exhibiting a growth rate (CAGR) of 60.1% during 2024-2032.

-

Europe leads the market, accounting for the largest 3D concrete printing market share.

-

Based on the product type, the market has been divided into walls, floors and roofs, panels and lintels, staircases, and others.

-

On the basis of the concrete type, the market has been segregated into ready-mix, high-density, precast, shotcrete and others.

-

Gantry system remain a dominant segment in the market, as it offers superior precision, scalability, and flexibility for large-scale construction projects, making it highly efficient for printing complex and sizeable structures.

-

Residential building represents the leading end use segment.

-

The increasing urbanization and demand for affordable housing solutions is a primary driver of the 3D concrete printing market.

-

Advancements in material science, along with the rising investment in infrastructure development projects are reshaping the 3D concrete printing market.

Industry Trends and Drivers:

-

Growing demand for sustainable construction:

One of the primary drivers for the global 3D concrete printing market is the increasing demand for sustainable construction solutions. The traditional construction industry has long been associated with high levels of waste, energy consumption, and carbon emissions. However, with rising concerns about environmental impact and climate change, there has been a growing focus on adopting eco-friendly practices within construction. 3D concrete printing offers a significant advantage in this regard, as it allows for more precise use of materials, reducing waste and minimizing the carbon footprint of construction projects. By utilizing automated technology to print concrete structures layer by layer, the process eliminates the need for excess raw materials often wasted in traditional methods. Furthermore, it enables the design of complex geometries that optimize structural efficiency and reduce material consumption. The ability to create customized building components with fewer resources positions 3D concrete printing as an ideal solution for sustainable urban development.

-

Labor shortages in the construction industry:

The construction industry has been experiencing significant labor shortages, particularly in developed regions such as North America and Europe. The sector is facing challenges in attracting younger workers, leading to a decline in skilled labor availability. As a result, many construction companies are turning to automation technologies such as 3D concrete printing to fill the gaps caused by labor shortages. This technology can automate the process of constructing buildings, bridges, and infrastructure projects, significantly reducing the need for manual labor. 3D concrete printing also enhances productivity by accelerating project timelines, as it can work continuously without the need for breaks, unlike human labor. Moreover, it minimizes the risk of human error and improves construction safety by reducing the number of workers on-site. With its ability to streamline operations and reduce labor costs, the adoption of 3D concrete printing is becoming an attractive solution for companies aiming to mitigate labor-related challenges.

-

Rising adoption of prefabrication and modular construction:

The growing preference for prefabrication and modular construction is another key driver for the global 3D concrete printing market. Prefabrication involves manufacturing building components off-site in controlled environments and then assembling them on-site. This approach improves construction efficiency, reduces project timelines, and minimizes disruptions at the construction site. 3D concrete printing complements prefabrication by enabling the rapid production of complex, customized building elements in factories or other controlled environments. Modular construction, which involves assembling fully constructed units into a complete structure, is also gaining popularity, especially in sectors such as residential, commercial, and healthcare. 3D concrete printing can play a crucial role in creating highly accurate and durable modules that can be easily transported and assembled. This method reduces construction time and enhances quality control by ensuring precision in every component produced.

For an in-depth analysis, you can request a sample copy of the report: https://www.imarcgroup.com/3d-concrete-printing-market/requestsample

3D Concrete Printing Market Report Segmentation:

Breakup By Product Type:

-

Walls

-

Floors and Roofs

-

Panels and Lintels

-

Staircases

-

Others

Based on the product type, the market has been divided into walls, floors and roofs, panels and lintels, staircases, and others.

Breakup By Concrete Type:

-

Ready-mix

-

High-density

-

Precast

-

Shotcrete

-

Others

On the basis of the concrete type, the market has been segregated into ready-mix, high-density, precast, shotcrete and others.

Breakup By Printing Type:

-

Gantry System

-

Robotic Arm

Gantry system dominates the market due to its ability to accommodate large-scale construction projects with high precision and efficiency.

Breakup By End Use:

-

Residential Building

-

Commercial Building

-

Infrastructure

-

Others

Residential building holds the maximum number of shares as 3D concrete printing significantly reduces construction time and costs while offering greater design flexibility, making it highly attractive for the growing demand for affordable housing solutions.

Breakup By Region:

-

North America (United States, Canada)

-

Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

-

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

-

Latin America (Brazil, Mexico, Others)

-

Middle East and Africa

Europe holds the leading position owing to a large market for 3D concrete printing driven by its strong emphasis on sustainable construction practices, advanced technological infrastructure, and significant investment in research and development for innovative building solutions.

Top 3D Concrete Printing Market Leaders:

-

Apis Cor

-

COBOD International A/S

-

CyBe Construction B.V.

-

DUS Architects

-

Foster + Partners

-

Heidelbergcement AG

-

Holcim Ltd

-

Sika AG

-

Skanska AB

-

Universe Architecture

-

XtreeE

-

Yingchuang Building Technique Co. Ltd.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Browse Other Reports

-

Party Supplies Market Size, Share and Industry Analysis, Report 2024-2032

-

Luxury Cosmetics Market Size, Share, Growth and Industry Analysis, Report 2024-2032

-

Salmon Market Size, Share and Market Analysis, Report 2024-2032

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Media Contact

Company Name: IMARC Group

Contact Person: Elena Anderson

Email: Send Email

Phone: +1-631-791-1145

Address:134 N 4th St.

City: Brooklyn

State: NY

Country: United States

Website: https://www.imarcgroup.com