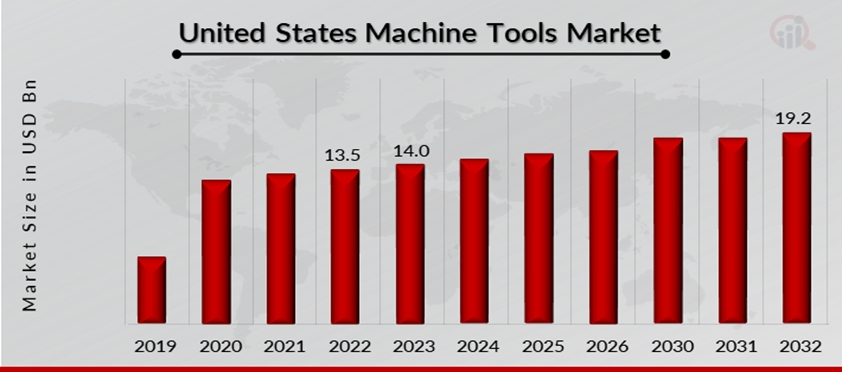

Market Research Future published a report titled, the United States Machine Tools Market Size, Share, Competitive Landscape and Trend Analysis Report by Type, End User, and Region: Opportunity Analysis and Industry Forecast till 2032. the United States Machine Tools market size was valued at USD 13.5 billion in 2022. The United States Machine Tools market industry is projected to grow from USD 14.4 Billion in 2023 to USD 19.2 Billion by 2032, CAGR of 4.0% during the forecast period 2024 – 2032.

United States Machine Tools Market Overview

The United States machine tools market plays a crucial role in the country’s manufacturing sector, contributing significantly to industrial production, automation, and innovation. Machine tools are essential equipment used for cutting, shaping, and finishing metal or other materials, enabling manufacturers to produce high-precision components for various industries, including automotive, aerospace, defense, construction, and electronics.

The market has experienced consistent growth due to advancements in automation, increased adoption of smart manufacturing technologies, and the rising demand for customized machinery. The integration of Industry 4.0 principles, such as IoT and AI-driven automation, has also propelled the U.S. machine tools industry forward, ensuring higher efficiency and precision.

Get Free Sample PDF Brochure: https://www.marketresearchfuture.com/sample_request/21437

Key Companies in the United States Machine Tools Market include

- TRUMPF Inc.

- Haas Automation Inc.

- Amada Co. Ltd

- Lincoln Electric Holdings Inc.

- Multipress Inc.

- MITUSA Inc.

- MC Machinery Systems Inc.

- Mate Precision Tooling Inc.

- Bystronic Inc.

- Laser Mechanisms Inc.

- Koike Aronson Inc./Ransome6

- FENN Metal Forming Machinery Solutions

- Cincinnati Inc.

Market Trends Highlights

Several trends are shaping the U.S. machine tools market, driving its expansion and innovation. One key trend is the increasing adoption of CNC (Computer Numerical Control) machines, which enhance precision, efficiency, and repeatability in manufacturing processes. Another significant trend is the rise of additive manufacturing and 3D printing technologies, which are complementing traditional machine tools by enabling rapid prototyping and complex part production.

Additionally, there is a growing emphasis on energy-efficient and sustainable machine tools as manufacturers seek to reduce their environmental footprint. Automation and robotics integration into machine tool systems are also gaining traction, allowing companies to improve productivity and reduce labor costs. Furthermore, the demand for customized and flexible machine tools is rising, driven by the need for greater adaptability in production processes.

United States Machine Tools Market Dynamics

The U.S. machine tools market operates in a dynamic landscape influenced by technological advancements, economic conditions, trade policies, and evolving industry requirements. The market’s growth is fueled by increased capital investment in advanced manufacturing solutions, particularly from the automotive and aerospace sectors.

The U.S. government’s focus on reshoring manufacturing and reducing dependency on imports has also provided a boost to domestic machine tool manufacturers. However, the market is subject to fluctuations in raw material prices, global supply chain disruptions, and competition from international manufacturers. Companies in the sector are continuously investing in research and development (R&D) to maintain competitiveness and offer cutting-edge solutions to meet evolving consumer demands.

Market Drivers

One of the primary drivers of the U.S. machine tools market is the rapid advancement in digital manufacturing technologies. The integration of smart sensors, AI-powered analytics, and cloud computing has enabled predictive maintenance, real-time monitoring, and enhanced machine performance. Another major driver is the increasing demand for high-precision components in the aerospace and automotive industries, where stringent quality standards require advanced machining capabilities.

The expansion of the construction and infrastructure sectors also fuels the demand for machine tools used in producing construction equipment and structural components. Additionally, government initiatives promoting domestic manufacturing, such as tax incentives and subsidies for industrial automation, have encouraged companies to invest in modern machine tools. The growth of electric vehicle (EV) production has further driven the need for specialized machining solutions to manufacture battery components and lightweight vehicle parts.

Market Restraints

Despite the promising growth, the U.S. machine tools market faces several challenges. One major restraint is the high initial cost associated with purchasing and maintaining advanced machine tools, particularly CNC systems and automated solutions. Small and medium-sized enterprises (SMEs) often struggle to afford these investments, limiting market penetration. Another constraint is the shortage of skilled labor, as the machine tool industry requires highly trained operators and engineers to manage complex machinery.

Trade uncertainties and fluctuating tariffs on imported machine tool components also pose a challenge, impacting the cost structure of domestic manufacturers. Additionally, global supply chain disruptions, exacerbated by geopolitical tensions and pandemics, have created volatility in the availability of raw materials and critical machine components. Cybersecurity risks associated with digital manufacturing technologies further present a barrier to the widespread adoption of connected machine tools.

Buy Now Premium Research Report: https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=21437

United States Machine Tools Market Segmentations

The U.S. machine tools market can be segmented based on type, application, and end-user industry.

By Type:

Milling Machines – Used for shaping metal and other materials with rotating cutting tools.

Lathe Machines – Employed in metalworking to rotate workpieces for cutting, sanding, or drilling.

Grinding Machines – Utilized for finishing processes requiring high surface quality and precision.

Drilling Machines – Essential for creating precise holes in metal and non-metal materials.

Electrical Discharge Machines (EDM) – Used in precision machining applications where traditional cutting tools may not be effective.

Additive Manufacturing Machines – Includes 3D printing solutions used in prototyping and complex part production.

By Application:

Metal Cutting – Accounts for the largest market share, used in various industrial applications.

Metal Forming – Includes bending, forging, and stamping processes essential for manufacturing complex shapes.

Others – Includes specialized applications such as composite material machining.

By End-User Industry:

Automotive – High demand for precision machining in vehicle components and engine parts.

Aerospace & Defense – Stringent standards necessitate high-precision machining for aircraft components.

Construction & Infrastructure – Machine tools used in heavy machinery production and structural fabrication.

Electronics – Miniaturization of electronic components drives demand for precision machining.

Medical Devices – Increasing demand for high-precision machining in medical equipment and implants.

Future Trends

The future of the U.S. machine tools market is expected to be shaped by several transformative trends. The continued rise of automation and AI-driven manufacturing will lead to greater efficiency, predictive maintenance capabilities, and real-time process optimization. The expansion of Industry 4.0 will further drive the adoption of smart, connected machine tools that integrate with digital supply chains. The shift towards sustainability and eco-friendly manufacturing will push companies to invest in energy-efficient and recyclable machine tools.

Additionally, hybrid manufacturing combining additive and subtractive manufacturing processes is expected to gain momentum, enabling cost-effective and flexible production. The rise of electric vehicles will continue to create demand for specialized machining solutions, particularly for lightweight materials and battery production. Lastly, government policies supporting domestic manufacturing and R&D investments will further bolster market growth, ensuring the U.S. machine tools industry remains globally competitive.

More Related Reports:

Gas Detection Equipment Market

About Market Research Future

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research Consulting Services. The MRFR team have a supreme objective to provide the optimum quality market research and intelligence services for our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Media Contact

Company Name: Market Research Future

Contact Person: Media Relations

Email: Send Email

Country: United States

Website: https://www.marketresearchfuture.com