Automotive Shredded Residue (ASR), also known as auto fluff, is the non-metallic waste left after end-of-life vehicles (ELVs) are shredded for metal recovery. It consists of plastics, rubber, glass, textiles, and residual metals. The demand for ASR recycling and recovery is rising due to stringent environmental regulations, sustainability goals, and circular economy initiatives. With growing focus on material recovery, waste-to-energy solutions, and landfill reduction, the automotive and recycling industries are investing in advanced sorting, pyrolysis, and incineration technologies to manage ASR effectively. The report provides a professional in-depth examination of the industry current scenario, CAGR, gross margin, revenue, price, automotive shredded residue (ASR) market growth rate, volume, value, market share, and growth are among the market data assessed and re-validation in the research. The Automotive shredded residue (ASR) market is projected to reach USD 1.6 billion by 2028, at a CAGR of 6.6% from USD 1.1 billion in 2023.

The growth of the automotive shredded residue (ASR) market is primarily driven by escalating resource scarcity and a growing need for recycled materials. Regulatory pressures from government and environmental agencies, coupled with ongoing technological innovations in post-shredder technology, further contribute to its expansion.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=162123480

“Plastics by composition is projected to be the largest, in terms of value, during the forecast period.”

Various industries, particularly packaging, automotive, and consumer goods, are witnessing a growing demand for recycled plastics as companies seek sustainable materials that align with environmental objectives. Governments across many countries are implementing regulations and offering incentives to encourage recycling and the utilization of recycled materials. These regulatory measures can stimulate investments in post-shredder technologies for plastics. The concept of a circular economy, which promotes the reuse and recycling of materials rather than disposal, is gaining traction. This momentum encourages the development of technologies that efficiently process and recycle plastics into new products. Heightened public awareness of plastic pollution in oceans and ecosystems has led to calls for more effective recycling and waste management solutions, prompting investments in technologies capable of handling post-shredder plastics with greater efficiency.

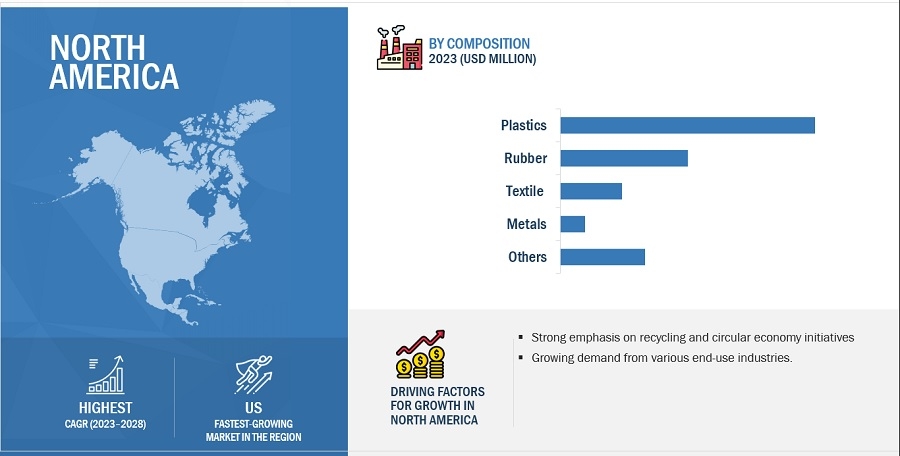

“North America is expected to be the fastest growing market for post shredder technology during the forecast period, in terms of value.”

The adoption of post shredder technology in the North American region is attributed to several driving factors. North America, especially the United States and Canada, is characterized by a robust industrial and manufacturing sector that generates substantial volumes of industrial and post-consumer waste, creating a demand for efficient processing and recycling solutions like post shredder technology. The region also navigates a complex regulatory landscape woven with federal, state, and provincial regulations governing waste management and recycling, propelling the necessity for advanced technologies to meet regulatory standards and optimize recycling processes. Furthermore, North America showcases a growing environmental consciousness among consumers and businesses, fueling a heightened demand for recycling and waste reduction solutions and thereby bolstering the automotive shredder residue (ASR) market. Additionally, North America has a history of significant investments in research and development, fostering the advancement and adoption of state-of-the-art recycling technologies and contributing to the expansion of the post-shredder technology market. The region’s wealth of resources, including valuable metals and plastics crucial for recycling processes, acts as an incentive for investments in recycling technologies. Importantly, key industries within North America, such as automotive, manufacturing, and packaging, demonstrate a robust appetite for recycled materials, serving as a catalyst for the development of technologies that efficiently handle post-shredder materials.

Automotive Shredded Residue (ASR) Companies

The key players in this market are Tomra Systems ASA (Norway), Gallo (Belgium), Sims Limited (Australia), MBA Polymers Inc.(US), and Binder+Co. (Austria), PLANIC (Japan), Axion Ltd.(UK), SRW Metal float GmbH (Germany), Machinex Industries, Inc. (Canada), Wendt Corporation (US), CP Manufacturing Inc. (US), BT-Wolfgang Binder GmbH (Austria), Agilyx (US), Steinert (Germany), etc. These companies demonstrate a robust presence in their local markets and are actively exploring opportunities for geographical diversification to expand their operations. Their strategic emphasis lies in expanding their market footprint by introducing new products and persuing different avenues for growth.

Get a Sample Copy of This Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=162123480

Tomra Systems ASA

Established in 1972, Tomra Systems ASA initially focused on designing, manufacturing, and selling reverse vending machines (RVMs) for the automated collection of used beverage containers. Today, the company has evolved into a technology-driven company that plays a crucial role in advancing the circular economy. They offer cutting-edge solutions in collection and sorting systems, as well as food processing, incorporating sensor-based sorting and grading technology. The company is headquartered in Asker Municipality in Norway.

The company operates through three primary business segments: Collection, Recycling, and Food. It offers a diverse range of solutions in areas such as Food, Mining, Reverse vending, and Recycling.

In total, Tomra has installed around 105,000 systems across more than 100 markets globally. The Tomra Group has a global workforce of 5,000 employees and is a publicly-traded company. TOMRA has a widespread presence, spanning all continents and offering its services in regions like Asia-Pacific, Europe, The Americas, and beyond.

Gallo

Galloo is a prominent European recycling company specializing in ferrous and non-ferrous metals. The company utilizes post-shredder technology, which involves additional processing of materials after shredding. Galloo company boasts a robust plastics recycling production capacity of 90,000 tons per year. Galloo Plastics, a specialized division within the Galloo Group, specializes in plastic processing. Through strategic investments, Galloo Recycling Group boasts an extensive network with over 40 divisions spread across Belgium, France, and The Netherlands.

Sims Limited

Established in 1917, Sims Limited stands as a prominent global figure in metal recycling, as well as offering circular solutions for technology and emerging as a leader in renewable energy. Sims Limited also engages in the processing of ferrous metals for subsequent resale, employing a range of techniques such as sorting, shredding, cutting, torching, baling and breaking. The company’s focal point on employing advanced machine sorting methods like Eddy Current Systems for industrial, consumer and vehicle scrap metal enabling it to achieve elevated rates of metal recovery. Operating under a subsidiary of Sims Limited, Sims Resource Renewal shares a collective mission to contribute to a waste free world and the conservation of our planet. The company’s objective entails utilizing over 1 million tons of Automotive Shredder Residue (ASR) annually by 2030, transforming this material into new innovative products.With a workforce of 4,000 individuals, Sims Limited has over 260 facilities spanning across 15 countries. The company possesses processing facilities across the Americas, EMEA and APAC regions.

Inquire Before Buying: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=162123480

MBA Polymers Inc.

In1997, MBA Polymers Inc. was established in California. The company started operating as a modest production facility in Richmond, Virginia. Through years of unwavering commitment and strategic investments, MBA Polymers Inc. emerged as a global frontrunner in recycling plastics from end-of-lfe durable goods including computers, electronic appliances and automobiles. MBA Polymers Inc. serves as both a research and development center and a hub for managing licenses and intellectual property. The company has obtained over 40 patents worldwidefor its advancements.

Since 2001, MBA Polymers Inc. has established five clean-tech facilities in Germany, Austria, China,The UK and the US. These facilities have an impressive annual capacity of over 150,000 tons, which makes them the most advanced plastic recycling facilities in the world.

Binder+Co.

Binder+Co. is a global leader in providing sorting and processing solutions for industries such as recycling, mining, and raw materials. With a strong focus on sustainability and resource efficiency, the company designs, manufactures, and supplies advanced equipment and technologies that contribute to the effective sorting and processing of materials, promoting a circular economy and environmental responsibility. The company operates in the key business segments of packaging technology, processing technology and environmental technology. The company provides its sorting equipment through the environmental technology segment. The company specializes in the development and production of cutting-edge sorting equipment and technologies. These solutions are designed to efficiently separate and classify materials based on their properties like shape,size, colouer and composition.

Binder+Co. has a strong global presence and serves customers in various regions worldwide. The company is headquartered in Gleisdorf (Austria). In addition to its central location in Austria, the company has well established international footprint with subsidiaries and sales offices in key regions including Europe, Asia, North America, South America and Africa.

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America’s best management consulting firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

Earlier this year, we made a formal transformation into one of America’s best management consulting firms as per a survey conducted by Forbes.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ‘GIVE Growth’ principle, we work with several Forbes Global 2000 B2B companies – helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

Media Contact

Company Name: MarketsandMarkets™ Research Private Ltd.

Contact Person: Mr. Rohan Salgarkar

Email: Send Email

Phone: 18886006441

Address:1615 South Congress Ave. Suite 103, Delray Beach, FL 33445

City: Florida

State: Florida

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/automotive-shredded-residue-asr-market-162123480.html