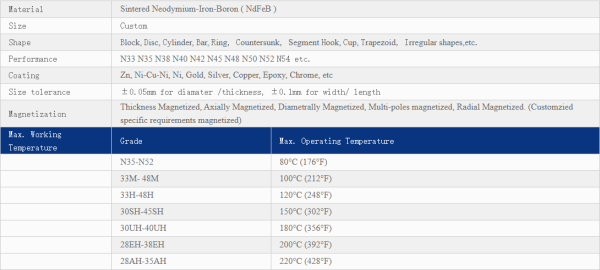

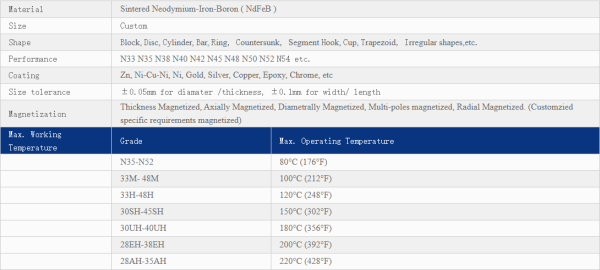

Size and shape:

We can provide customized disc, cylinder, ring, square cube, rectangular block, arc, countersunk, hook and other irregular permanent magnets.

Manufacture:

We use automatation equipments to cut and grind the raw materials to make the dimantions of the permanent magnet you want, with micro tolerance, to achieve the finishing effect.

Surface treatment:

Permanent magnets are easy to be oxidized. According to customer needs, the surface will be coated, epoxy coated or electroplated to prevent corrosion. We can provide nickel plating, galvanization, electrophoresis and other services.

Temperature Notes:

Permanent magnet is temperature sensitive. We will strictly produce according to the customer’s demand for permanent magnets with high temperature resistance.

Custom guide

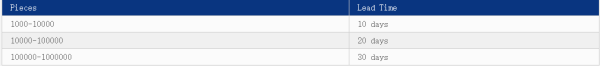

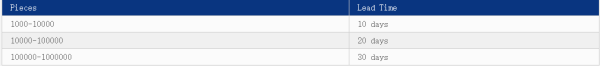

MOQ & Lead Time

Magnet performance

There are mainly the following three performance parameters to determine the performance of the magnet:

Remanence Br: After the permanent magnet is magnetized to technical saturation and the external magnetic field is removed, the retained Br is called the residual magnetic induction.

Coercive force Hc: To reduce the B of the permanent magnet magnetized to technical saturation to zero, the required reverse magnetic field strength is called the magnetic induction coercive force, abbreviated as coercive force.

Magnetic energy product BH: It represents the magnetic energy density established by the magnet in the air gap space (the space between the two magnetic poles of the magnet), that is, the static magnetostatic energy per unit volume of the air gap. Since this energy is equal to the product of the magnet’s Bm and Hm, it is called the magnetic energy product.

We can customize permanent magnets with properties between N35-N54 on the market.

Parameter of Magnets

| Grade |

Remanence |

Coercive Force |

Intrinsic Coercive Force |

Maximum Energy Product |

Working Temp |

| Br |

Hcb |

Hcj |

BH max |

Tw |

| mT |

KGs |

kA/m |

kOe |

kA/m |

kOe |

kJ/m3 |

MGOe |

| N35 |

1170-1220 |

11.7-12.2 |

≥868 |

≥10.9 |

≥955 |

≥12 |

263-287 |

33-36 |

80℃ |

| N38 |

1220-1250 |

12.2-12.5 |

≥899 |

≥11.3 |

≥955 |

≥12 |

287-310 |

36-39 |

80℃ |

| N40 |

1250-1280 |

12.5-12.8 |

≥923 |

≥11.6 |

≥955 |

≥12 |

302-326 |

38-41 |

80℃ |

| N42 |

1280-1320 |

12.8-13.2 |

≥923 |

≥11.6 |

≥955 |

≥12 |

318-342 |

40-43 |

80℃ |

| N45 |

1320-1370 |

13.2-13.7 |

≥876 |

≥11.0 |

≥955 |

≥12 |

342-366 |

43-46 |

80℃ |

| N48 |

1370-1420 |

13.7-14.2 |

≥892 |

≥11.2 |

≥955 |

≥12 |

366-390 |

46-49 |

80℃ |

| N50 |

1390-1440 |

13.9-14.4 |

≥836 |

≥10.5 |

≥955 |

≥12 |

374-406 |

47-51 |

80℃ |

| N52 |

1420-1470 |

14.2-14.7 |

≥836 |

≥10.5 |

≥876 |

≥11 |

390-422 |

49-53 |

80℃ |

| N55 |

1460-1520 |

14.6-15.2 |

≥716 |

≥9 |

≥876 |

≥11 |

414-446 |

52-56 |

80℃ |

| 35M |

1170-1220 |

11.7-12.2 |

≥868 |

≥10.9 |

≥1114 |

≥14 |

263-287 |

33-36 |

100℃ |

| 38M |

1220-1250 |

12.2-12.5 |

≥899 |

≥11.3 |

≥1114 |

≥14 |

287-310 |

36-39 |

100℃ |

| 40M |

1250-1280 |

12.5-12.8 |

≥923 |

≥11.6 |

≥1114 |

≥14 |

302-326 |

38-41 |

100℃ |

| 42M |

1280-1320 |

12.8-13.2 |

≥995 |

≥12.0 |

≥1114 |

≥14 |

318-342 |

40-43 |

100℃ |

| 45M |

1320-1370 |

13.2-13.7 |

≥995 |

≥12.5 |

≥1114 |

≥14 |

342-366 |

43-46 |

100℃ |

| 48M |

1360-1420 |

13.6-14.2 |

≥1019 |

≥12.8 |

≥1114 |

≥14 |

366-390 |

46-49 |

100℃ |

| 50M |

1390-1440 |

13.9-14.4 |

≥1035 |

≥13.0 |

≥1114 |

≥14 |

374-406 |

47-51 |

100℃ |

| 52M |

1420-1470 |

14.2-14.7 |

≥995 |

≥12.5 |

≥1035 |

≥13 |

390-422 |

49-53 |

100℃ |

| 33H |

1130-1170 |

11.3-11.7 |

≥836 |

≥10.5 |

≥1353 |

≥17 |

247-271 |

31-34 |

120℃ |

| 35H |

1170-1220 |

11.7-12.2 |

≥868 |

≥10.9 |

≥1353 |

≥17 |

263-287 |

33-36 |

120℃ |

| 38H |

1220-1250 |

12.2-12.5 |

≥899 |

≥11.3 |

≥1353 |

≥17 |

287-310 |

36-39 |

120℃ |

| 40H |

1250-1280 |

12.5-12.8 |

≥923 |

≥11.6 |

≥1353 |

≥17 |

302-326 |

38-41 |

120℃ |

| 42H |

1280-1320 |

12.8-13.2 |

≥955 |

≥12.0 |

≥1353 |

≥17 |

318-342 |

40-43 |

120℃ |

| 45H |

1320-1370 |

13.2-13.7 |

≥971 |

≥12.2 |

≥1353 |

≥17 |

342-366 |

43-46 |

120℃ |

| 48H |

1360-1420 |

13.6-14.2 |

≥1027 |

≥12.9 |

≥1353 |

≥17 |

366-390 |

46-49 |

120℃ |

| 50H |

1390-1440 |

13.9-14.4 |

≥1035 |

≥13.0 |

≥1274 |

≥16 |

374-406 |

47-51 |

120℃ |

| 52H |

1420-1470 |

14.2-14.7 |

≥1035 |

≥13.0 |

≥1274 |

≥16 |

390-422 |

49-53 |

120℃ |

| 28SH |

1040-1090 |

10.4-10.9 |

≥780 |

≥9.8 |

≥1592 |

≥20 |

207-231 |

25-28 |

150℃ |

| 30SH |

1080-1130 |

11.3-11.7 |

≥804 |

≥10.1 |

≥1592 |

≥20 |

223-247 |

28-31 |

150℃ |

| 33SH |

1130-1170 |

11.3-11.7 |

≥844 |

≥10.6 |

≥1592 |

≥20 |

247-271 |

31-34 |

150℃ |

| 35SH |

1170-1220 |

11.7-12.2 |

≥876 |

≥11 |

≥1592 |

≥20 |

263-287 |

33-36 |

150℃ |

| 38SH |

1220-1250 |

12.2-12.5 |

≥907 |

≥10.5 |

≥1592 |

≥20 |

287-310 |

36-39 |

150℃ |

| 40SH |

1250-1280 |

12.5-12.8 |

≥939 |

≥11.8 |

≥1592 |

≥20 |

302-326 |

38-41 |

150℃ |

| 42SH |

1280-1320 |

12.8-13.2 |

≥971 |

≥12.2 |

≥1592 |

≥20 |

318-342 |

40-43 |

150℃ |

| 45SH |

1320-1370 |

13.2-13.7 |

≥979 |

≥12.3 |

≥1592 |

≥20 |

342-366 |

43-46 |

150℃ |

| 50SH |

1390-1440 |

13.9-14.4 |

≥995 |

≥12.5 |

≥1592 |

≥19 |

374-406 |

47-51 |

150℃ |

| 52SH |

1420-1470 |

14.2-14.7 |

≥995 |

≥12.5 |

≥1592 |

≥19 |

390-422 |

49-53 |

150℃ |

| 28UH |

1020-1080 |

10.2-10.8 |

≥764 |

≥9.6 |

≥1990 |

≥25 |

207-231 |

25-28 |

180℃ |

| 33UH |

1130-1170 |

11.3-11.7 |

≥812 |

≥10.2 |

≥1990 |

≥25 |

247-271 |

31-34 |

180℃ |

| 35UH |

1170-1220 |

11.7-12.2 |

≥852 |

≥10.7 |

≥1990 |

≥25 |

263-287 |

33-36 |

180℃ |

| 38UH |

1220-1250 |

12.2-12.5 |

≥860 |

≥10.8 |

≥1990 |

≥25 |

287-310 |

36-39 |

180℃ |

| 40UH |

1250-1280 |

12.5-12.8 |

≥876 |

≥11.0 |

≥1990 |

≥25 |

302-326 |

38-41 |

180℃ |

| 42UH |

1270-1320 |

12.7-13.2 |

≥971 |

≥12.2 |

≥1990 |

≥25 |

310-342 |

39-43 |

180℃ |

| 50UH |

1390-1440 |

13.9-14.4 |

≥899 |

≥11.3 |

≥1990 |

≥25 |

374-406 |

47-51 |

180℃ |

| 52UH |

1420-1470 |

14.2-14.7 |

≥899 |

≥11.3 |

≥1990 |

≥25 |

390-422 |

49-53 |

180℃ |

| 28EH |

1020-1080 |

10.2-10.8 |

≥780 |

≥9.8 |

≥2388 |

≥30 |

207-231 |

25-28 |

200℃ |

| 30EH |

1080-1130 |

11.3-11.7 |

≥812 |

≥10.2 |

≥2388 |

≥30 |

223-247 |

28-31 |

200℃ |

| 33EH |

1130-1170 |

11.3-11.7 |

≥820 |

≥10.3 |

≥2388 |

≥30 |

247-271 |

31-34 |

200℃ |

| 35EH |

1170-1220 |

11.7-12.2 |

≥836 |

≥10.5 |

≥2388 |

≥30 |

263-287 |

33-36 |

200℃ |

| 28AH |

1020-1080 |

10.2-10.8 |

≥780 |

≥9.8 |

≥2706 |

≥34 |

207-231 |

25-28 |

230℃ |

| 30AH |

1070-1130 |

10.7-11.3 |

≥812 |

≥10.2 |

≥2706 |

≥34 |

215-247 |

27-31 |

230℃ |

| 33AH |

1110-1170 |

11.1-11.7 |

≥820 |

≥10.3 |

≥2706 |

≥34 |

239-271 |

30-34 |

230℃ |

Original Source: https://www.fullzenmagnets.com/custom-neodymium-magnets/