Technical Parameters

| Silo bottom: Hopper bottom silo | Silo capacity: 200 tonnes steel silo |

| Diameter: 6.7 meter | Silo Volume: 263 CBM |

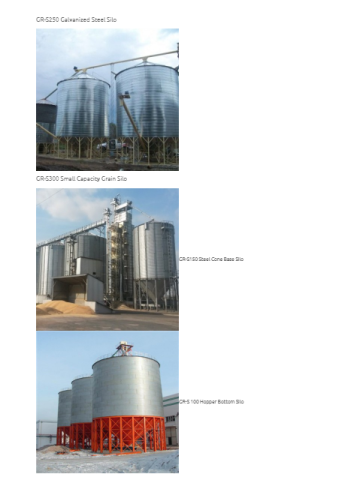

Galvanized steel conical bottom silo

The special design for conical bottom silo is full automatic unloading the grain from the silo, no need sweep auger,conical bottom can be made by concrete or steel, conical bottom silo columns designed [X” bracing, pressure bearing is higher than the national standard, and safe enough. Conical bottom silo body plate made by hot dip galvanized steel plate, zinc coating 275-600g/m2.

Assembly Hopper Bottom Silo Technical Parameters :

Silo bottom: Hopper bottom siloSilo capacity: 200 tonnes steel siloDiameter: 6.7 meterSilo Volume: 263 CBM

Assembly Hopper Bottom Silo Auxiliary System : 1. Ventilation System 2. Temperature Sensor System 3. Fumigation System 4. Thermal Insulation System Discharge: scraper conveyor

Assembly Hopper Bottom Silo wall plate processing step :

1. Raw steel plate feeding

2. Silo Wall Corrugated Molding Line

3. Computer punch on the silo plate surface

4. Finalize the design silo wall

5. Arc forming machine

6. Finished silo plate

Original Source: https://www.goldraintech.com/gr-s200-assembly-hopper-bottom-silo-product/

Media Contact

Company Name: Goldrain—-Grain Processing Equipment Specialist

Email: Send Email

Country: China

Website: https://www.goldraintech.com/