With the rapid development of high-tech, the warehousing industry is also undergoing unprecedented changes. Among them, the fully automatic four-way shuttle three-dimensional warehouse has undoubtedly become a remarkable innovation in recent years. This new type of warehousing system, with its high efficiency, automation intelligence, and flexible diversity, is overturning our understanding of traditional warehousing.

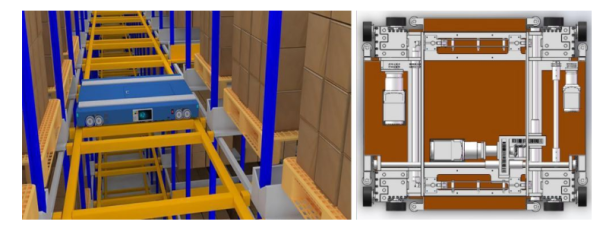

The fully automatic four-way shuttle car three-dimensional warehouse, as the name suggests, mainly stores and retrieves goods in the three-dimensional warehouse through the four-way shuttle car. This type of three-dimensional library usually consists of many shelves, each connected by a four-way shuttle car. The four-way shuttle can freely shuttle between shelves, achieving fast access to goods. Among them, the intelligent four-way shuttle is a type of vehicle that can achieve automated material storage and retrieval, automatic lane and layer changing, and automatic climbing; Capable of handling and driving on the ground; A high-tech logistics handling equipment that integrates functions such as automatic stacking, automatic handling, and unmanned guidance.

As an important component of intelligent warehousing systems, the demand for four-way shuttle vehicles continues to be released. At the same time, the number of manufacturers entering the field of four-way shuttle vehicles has been increasing year by year. The continuous improvement and innovation of technology have helped the rapid landing of four-way shuttle vehicles, as evidenced by the recent CeMAT Asia exhibition. From the perspective of demand characteristics, there are significant differences in the focus of demand among different industries. Scenarios such as a large number of SKUs, dense storage, and high-speed picking are typical application scenarios for four-way shuttle vehicles. At the same time, the personalized and customized needs of downstream customers are becoming more and more common. The flexible system solutions for four-way shuttle vehicles are receiving more and more attention from users and have begun to be promoted and applied in multiple industries, such as e-commerce, retail, 3C, medical, etc In sub sectors such as new energy, market demand continues to emerge, and industry penetration rates are increasing year by year.

Hebei Woke HEGERLS

Hebei Woke Metal Products Co., Ltd. was founded in 1996 and is one of the earliest companies in the shelf industry in North China. In 1998, it began to participate in the sales and installation of warehousing and logistics equipment. After more than 20 years of development, we have become a one-stop integrated warehousing and logistics service provider that integrates warehousing and logistics project design, equipment and facility production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, and more. We offer comprehensive, comprehensive, and high-quality warehousing and logistics services!

And establish the independent brand “HEGERLS”, with headquarters in Shijiazhuang and Xingtai production bases, and sales branches in Bangkok, Thailand, Kunshan, Jiangsu, and Shenyang. We have a production and research and development base of 60000 square meters, 48 world-class production lines, and more than 300 people engaged in research and development, production, sales, installation, and after-sales service. Among them, we have nearly 60 senior technicians and engineers. The Hagrid series of products and services covers nearly 30 provinces, cities, and autonomous regions in China. The products are exported to countries and regions such as Europe, America, the Middle East, Latin America, and Southeast Asia, and have achieved remarkable results overseas.

Products under HEGERLS:

Storage shelves: shuttle shelves, crossbeam shelves, four-way shuttle car shelves, pallet four-way shuttle car shelves, medium shelves, light shelves, pallet shelves, rotary shelves, through shelves, three-dimensional warehouse shelves, attic shelves, laminated shelves, cantilever shelves, mobile shelves, fluent shelves, driving in shelves, gravity shelves, high-level storage shelves, push in shelves, picking shelves Narrow aisle shelving, heavy-duty pallet shelving, shelf shelving, drawer shelving, cow leg shelving, multi-layer attic shelving, stacking shelving, three-dimensional high-level shelving, universal angle steel shelving, corridor shelving, mold shelving, dense cabinets, steel platforms, anti-corrosion shelving, and so on.

Storage equipment: steel structure platform, steel material box, smart frame, storage cage, isolation net, elevator, shuttle car, two-way shuttle car, parent-child shuttle car, four-way shuttle car, stacker crane, mesh partition, high-altitude vehicle, intelligent conveying and sorting equipment, pallet, electric forklift, container, turnover box, AGV, etc.

New intelligent robot series: namely the Kubao robot series, this series of products includes: cardboard box picking robot HEGERLS A42N, lifting picking robot HEGERLS A3, double depth bin robot HEGERLS A42D, telescopic lifting bin robot HEGERLS A42T, laser SLAM multi-layer bin robot HEGERLS A42 SLAM, multi-layer bin robot HEGERLS A42, dynamic width box robot HEGERLS A42-FW, intelligent management platform, workstation Intelligent charging station.

Automated three-dimensional warehouses: shuttle type three-dimensional warehouses, crossbeam type three-dimensional warehouses, pallet type three-dimensional warehouses, heavy-duty shelf three-dimensional warehouses, automated warehousing three-dimensional warehouses, attic three-dimensional warehouses, layer board three-dimensional warehouses, four-way shuttle vehicle three-dimensional warehouses, mobile three-dimensional warehouses, narrow aisle three-dimensional warehouses, unit type three-dimensional warehouses, through type three-dimensional warehouses, cargo format three-dimensional warehouses, automated cabinet type three-dimensional warehouses, strip shelf three-dimensional warehouses, picking type three-dimensional warehouses, and semi-automatic three-dimensional warehouses Linear guide rail type three-dimensional storage, U-shaped guide rail type three-dimensional storage, lateral guide rail type three-dimensional storage, low level three-dimensional storage, middle level three-dimensional storage, high-rise three-dimensional storage, integrated three-dimensional storage, layered three-dimensional storage, stacker crane type three-dimensional storage, circular shelf three-dimensional storage, and so on.

Warehouse Management System: Order Management System (OMS), Warehouse Management System (WMS), Warehouse Control System (WCS), Warehouse Scheduling System (RCS), etc. The warehouse management system provided by Hegerls can promote the efficiency improvement and cost reduction of the entire chain, achieving true “intelligent warehouse distribution integration”.

About the HEGERLS four-way shuttle system

The HEGERLS four-way shuttle car independently developed by Hebei Woke can operate smoothly in ambient temperatures ranging from -18 ℃ to+40 ℃, and is perfectly integrated with WCS/WMS. Through the use of computational intelligence, ultra-low latency communication networking and other technologies, it breaks through the bottlenecks of traditional container stackers and straight line shuttle cars in terms of autonomous scheduling, path optimization, system efficiency, space limitations, and other aspects. Not only that, but also multi vehicle collaborative operation has been achieved to meet the storage needs of high density and high flow, making inbound and outbound and picking operations more efficient.

The HEGERLS four-way shuttle system can also use the cross aisle function to “unbind” the aisle from the elevator, effectively solving the bottleneck problems faced by traditional shuttle vehicles. That is to say, the HEGERLS four-way shuttle system can fully configure the car according to the customer’s work flow, minimizing idle vehicle situations and improving car mobility.

Of course, in order to avoid the high conflict rate of multi vehicle operations in the same area and affect efficiency, the concept of dynamic partitioning has been specially added. Based on the real-time distribution of tasks, the range of the area is changed, and multiple vehicles in a dynamic area can interfere with each other to reduce interference, meet the needs of task allocation, improve the mobility of vehicles, and achieve the effect of multi vehicle avoidance.

In this regard, with the support of efficient intelligent scheduling algorithms, the HEGERLS four-way shuttle system is suitable for both low traffic and high-density storage, as well as high traffic and high-density storage picking; The mutual substitution and backup between four-way shuttle cars is also the best solution for the existing needs of customers. Realize flexible transformation without affecting the existing business engineering of the customer, and flexibly add/delete equipment according to the site, with quite flexible configuration.

Next, Hebei Woke will continue to increase the further integration of artificial intelligence and various sub industry solutions, leading the development direction of the new generation of logistics technology. With cutting-edge artificial intelligence technology, innovative product systems, hardware research and development manufacturing, software development, and high-quality project management capabilities, we adhere to providing comprehensive one-stop services for major enterprise users. With intelligent solutions, we help enterprises upgrade their digitalization, improve the cost-effectiveness and flexibility of the entire supply chain, and enable users of major enterprises to truly enjoy logistics automation More convenience brought by intelligent logistics solutions.

Original Source: https://www.wkrack.com/news/how-can-the-hegerls-four-way-shuttle-system-avoid-conflict-barriers-caused-by-multiple-vehicle-operations-in-the-same-area/

Media Contact

Company Name: Hebei Woke Metal Products Co., Ltd.

Email: Send Email

Address:Room 1118, Building No.6, Tatan Mall, Tatong Street, Production base: 68 Shidai Road, Xinhe Industrial Park

City: Shijiazhuang

State: Hebei Province

Country: China

Website: https://www.wkrack.com/