With the rapid development of automation and intelligent logistics technology, the four-way shuttle system solution for pallets has attracted more and more attention from users due to advantages such as high density and flexibility. It has been widely applied in multiple industries, such as e-commerce, retail, 3C electronics, new energy, mechanical manufacturing, automobiles and spare parts, food, clothing, medical, tobacco, cold chain, etc. The market demand continues to emerge, and the industry penetration rate is increasing year by year.

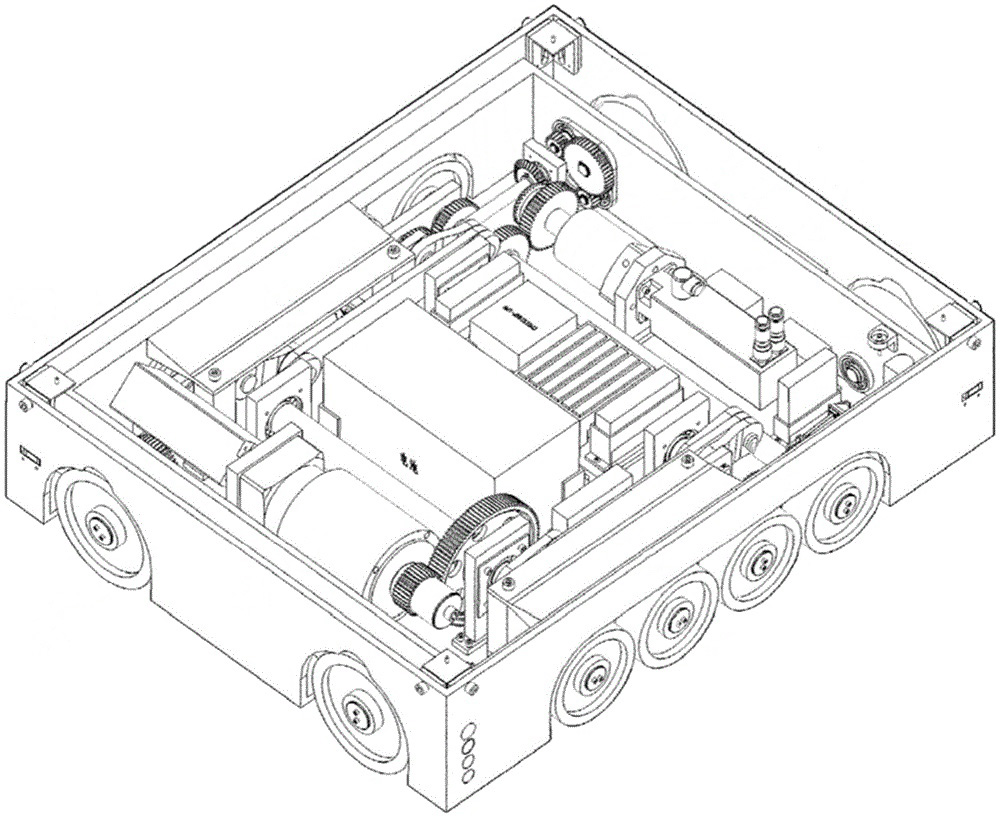

As one of the earliest domestic enterprises to enter the research and development and production of shuttle equipment, Hebei Woke has always adhered to the spirit of precision in product and technology, carefully crafted each device, and provided scenario based product solutions according to different working conditions of customers. And in 1998, we launched our independently developed Hegerls shuttle car product. So far, Hegerls shuttle car products have covered different series such as box type two-way shuttle cars, tray type two-way shuttle cars, tray type shuttle mother cars, box type four-way shuttle cars, and tray type four-way shuttle cars. Among them, the Hegerls tray four-way shuttle is one of the core products that Hebei Woke focuses on building. This type of equipment has the advantages of efficient and dense storage functions, flexible expansion characteristics, and is suitable for operation modes with more product specifications and fewer batches. The Hegerls tray four-way shuttle adopts a modular design as a whole, which makes it more convenient and efficient to replace components when they fail, and also facilitates support from other small cars. All structural components are independently developed and produced by Hebei Woke, strictly controlling quality and accuracy. In terms of communication and positioning technology, Hebei Woke has selected positioning methods such as encoder positioning, laser positioning, barcode/QR code positioning, RFID positioning, etc. to achieve seamless roaming of the four-way shuttle vehicle in the warehouse, improve the vehicle’s anti-interference ability, enable automatic load balancing, and eliminate single points of failure.

The most critical scheduling system technology in the four-way shuttle vehicle for pallets is also the most concerning issue for users in major enterprises. Due to the involvement of multi vehicle scheduling and collaborative operations with related equipment such as elevators in the four-way tray vehicle system, the ability of scheduling software will directly have a significant impact on system efficiency.

It is worth mentioning that in addition to stable and reliable intelligent hardware products, Hebei Woke also has its independently developed super large cluster scheduling intelligent software – HEGERLS software platform. As a global central control system based on AI technology, HEGERLS software system can connect Hebei Woke’s own products and third-party automated and intelligent logistics equipment. Through AI algorithms, it can improve the intelligence level of four-way vehicles and achieve efficient collaboration of cluster operations. It can achieve global map management and prevent vehicle collisions; Real time path planning, flexible avoidance of conflicting paths; Configuration based vehicle additions and deletions, can be completed online in 1 minute; It is also possible to implement vehicle allocation optimization and select suitable vehicles to perform tasks; Adopting an intelligent automatic charging strategy, the vehicle can always be used online. The multi vehicle scheduling system has broken through the limitation of one vehicle at a time, not only improving system flexibility, but also enhancing overall system efficiency.

In recent years, Hebei Woke has continuously improved the body of the pallet four-way shuttle, greatly improving its operational efficiency and flexibility. Its application is no longer limited to storing goods on shelves, but can also be used in scenarios such as warehouse handling and picking. In the future, Hebei Woke will firmly grasp the strong momentum of intelligent warehousing development, always adhere to customer demand orientation, and continue to provide customers with high intelligence, high decision-making, and integrated intelligent warehouse overall solutions.

Media Contact

Company Name: Hebei Woke Metal Products Co., Ltd.

Email: Send Email

Address:Room 1118, Building No.6, Tatan Mall, Tatong Street, Production base: 68 Shidai Road, Xinhe Industrial Park

City: Shijiazhuang

State: Hebei

Country: China

Website: https://www.wkrack.com/