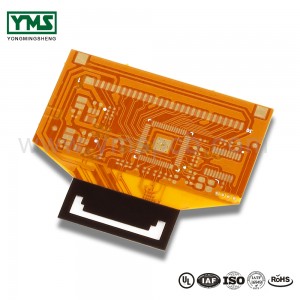

Next, Yong Ming Sheng flexible pcb manufacturing with you to understand that make flexible PCB.

flexible circuit board

Characteristics of flexible circuit board

1. Shortness: short assembly time

All lines are configured to complete, eliminating redundant wiring connection work;

2. Small: the volume is smaller than PCB(hard plate)

Can effectively reduce the volume of the product, increase the convenience of carrying;

Light: Lighter weight than PCB (hard board)

Can reduce the weight of the final product;

4. Thin: Thinner than PCB(hard board)

It can improve the softness and strengthen the assembly of three dimensional space in limited space.

Advantages of flexible circuit board

A flexible printed circuit board is a printed circuit made of soft insulating material. It has many advantages that hard printed circuit boards do not:

1. Free to bend, curl and fold, according to the spatial layout requirements, can be arranged, moved and expanded in the three-dimensional space, to realize the integration of components assembly and wire connection;

2. The use of FPC can greatly reduce the volume and weight of electronic products, to adapt to the development of electronic products to the direction of high density, small size, high reliability requirements.FPC is widely used in aerospace, military, mobile communications, notebooks, computer peripherals, PDA, digital cameras and other fields or products;

3. In addition, FPC also has good heat dissipation, weldability and easy assembly, and the overall cost is low, so the combination of hardware and soft design to a certain extent to compensate for the flexible substrate in the element carrying capacity.

Flexible printed circuit board

How to make flexible pcb?

According to the number of line layers, FPC flexible printed circuit board can be divided into single-sided FPC, double-sided FPC, multi-layer FPC, different line layer production process also has all the differences, taking single-sided FPC flexible printed circuit board, double-sided FPC flexible printed circuit board as an example.

Single FPC flexible printed circuit board production process: material – drilling – paste dry film – alignment – exposure – development – etching – film removal – surface treatment – lamination – pressing – curing – surface treatment – nickel plating – printing – cutting – electric testing – stamping – final inspection – packaging – shipment.

FPC flexible double-sided printed circuit board production process: cutting, drilling and PTH to plating, pretreatment to stick a dry film, para exposure and development – plating – to take off the film – stick dry film – para exposure, development and etching to take off the film, the surface treatment – films – the embossing – cure – heavy nickel – printing – shear to electric logging, cutting to final inspection, packaging and shipment.

Media Contact

Company Name: Huizhou Yongmingsheng Technology co., ltd.

Contact Person: Joyce

Email: Send Email

Phone: 0086-13902935069

Country: China

Website: https://www.ymspcb.com/