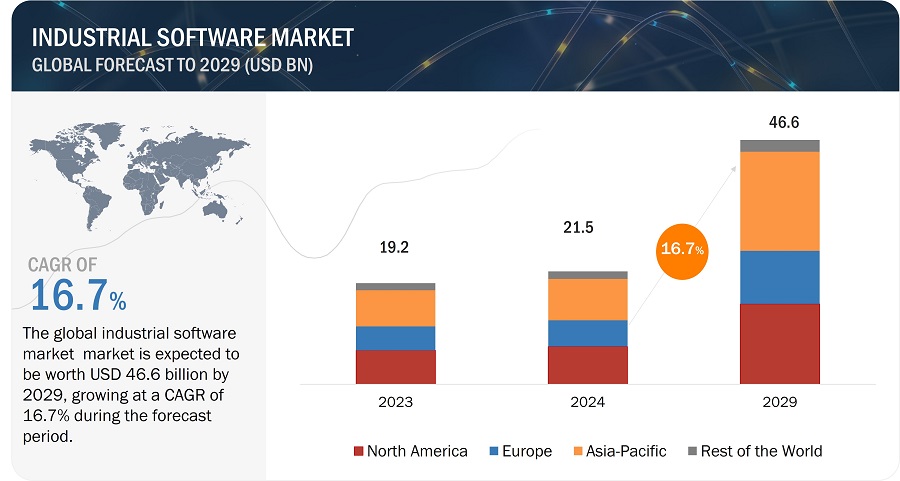

The report “Industrial Software Market by Type (Manufacturing Execution System, SCADA, Human Machine Interface, Robotic Software, Fault Detection and Classification, Al in manufacturing, Industrial Metrology), End-use (Process, Discrete) – Global Forecast to 2029” The global industrial software market is expected to be valued at USD 21.5 billion in 2024 and is projected to reach USD 46.6 billion by 2029; it is expected to grow at a CAGR of 16.7 % from 2024 to 2029.

The industrial software market is propelled by several key factors driving smart manufacturing and intelligent factory initiatives globally. Adopting Industry 4.0 technologies such as IoT, AI, big data analytics, and cloud computing is pivotal in enhancing operational efficiency and agility. Industrial software solutions like MES, SCADA, and HMI systems optimize production processes by providing real-time monitoring, resource management, and workflow automation, reducing downtime and improving productivity.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=27555137

Browse 162 market data Tables and 61 Figures spread through 263 Pages and in-depth TOC on “Industrial Software Market”

View detailed Table of Content here – https://www.marketsandmarkets.com/Market-Reports/industrial-software-market-27555137.html

These solutions also ensure compliance with stringent quality and regulatory standards in industries such as pharmaceuticals and automotive, enhancing product safety and regulatory adherence. Cost efficiency is achieved through better resource utilization and predictive maintenance strategies, contributing to overall cost savings.

Smart manufacturing practices supported by industrial software foster innovation in product design and manufacturing flexibility, accelerating time-to-market for new products and improving global competitiveness. Continuous technological advancements further expand the capabilities of industrial software, driving innovation and enabling more autonomous and interconnected manufacturing environments.

The automotive segment in the discrete industry is expected to grow fastest during the forecast period.

Industrial software plays a crucial role in automotive manufacturing, driving significant growth due to its ability to enhance efficiency, quality, and innovation across the production lifecycle. Automotive manufacturers rely on advanced software solutions such as Manufacturing Execution Systems (MES), SCADA/HMI, or robotic software to streamline design and assembly operations. MES systems optimize production schedules, monitor real-time performance, and ensure compliance with industry standards, thereby improving throughput and reducing costs. This software manages product data and lifecycle processes, facilitating collaboration among design teams and suppliers to accelerate time-to-market for new vehicle models. Moreover, the adoption of digital twins and AI-driven analytics enables predictive maintenance and quality control, minimizing defects and enhancing overall production reliability. The high growth in industrial software adoption within automotive manufacturing is driven by the industry’s continuous pursuit of operational excellence, innovation in smart manufacturing technologies, and the need to meet stringent regulatory requirements while maintaining a competitive advantage in a global market.

The Pharmaceuticals segment in process industries is projected to grow significantly during the forecast period.

Industrial software plays a pivotal role in pharmaceutical manufacturing. It is experiencing substantial growth due to its ability to optimize processes, ensure regulatory compliance, and enhance product quality and safety throughout the production cycle. Pharmaceutical companies utilize advanced software solutions, such as Manufacturing Execution Systems (MES), to manage and monitor manufacturing operations with precision and efficiency. MES systems enable real-time monitoring of production processes, ensuring adherence to strict quality standards and regulatory requirements while optimizing resource utilization. The high growth in industrial software adoption within pharmaceutical manufacturing is driven by increasing demand for personalized medicine, stringent regulatory oversight, and the industry’s continuous investment in technology to enhance operational efficiency and accelerate time-to-market for new drug formulations. These software solutions empower pharmaceutical companies to maintain high standards of product safety, reliability, and compliance while adapting to evolving market dynamics and consumer expectations.

Asia Pacific is expected to grow significantly throughout the forecast period.

Asia Pacific’s industrial software market is projected to grow significantly. In the Asia Pacific, initiatives promoting smart manufacturing and smart factory implementations are considerably shaping the industrial software market. Countries like China, Japan, South Korea, and Singapore lead efforts with strategic initiatives and investments tailored to advance manufacturing through cutting-edge technologies. China’s “Made in China 2025” initiative focuses on integrating AI, IoT, and robotics to enhance productivity and innovation in manufacturing. Japan’s “Society 5.0” vision aims to use digital technologies to revolutionize manufacturing efficiency and sustainability. South Korea’s “Manufacturing Industry Innovation 3.0” emphasizes IoT and cloud computing for smart manufacturing enhancements. Singapore supports digital transformation through its “Smart Industry Readiness Index” framework, guiding companies toward becoming smart factories. These initiatives propel the adoption of MES, SCADA, ERP, and analytics solutions, driving operational efficiency, cost reduction, and faster time-to-market for products. They collectively bolster the industrial software market by fostering innovation and competitiveness in manufacturing across the region.

Key Players

The industrial software market includes significant Tier I and II players such as Siemens (Germany), Rockwell Automation (US), ABB (Switzerland), Emerson Electric Co. (US) and General Electric (US), among others, are some of the key players in the industrial software market.

Media Contact

Company Name: MarketsandMarkets™ Research Private Ltd.

Contact Person: Mr. Rohan Salgarkar

Email: Send Email

Phone: 18886006441

Address:630 Dundee Road Suite 430

City: Northbrook

State: IL 60062

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/industrial-software-market-27555137.html