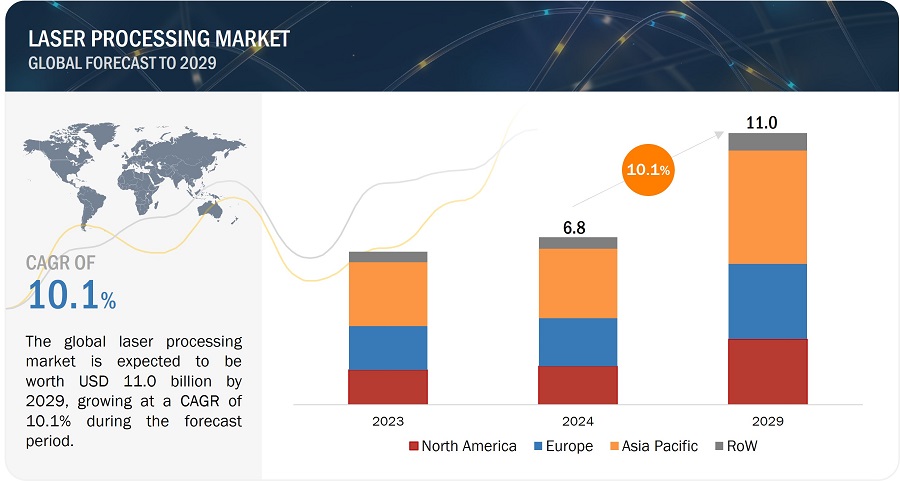

According to the new research report “Laser Processing Market by Laser Type (Solid Lasers, Liquid Lasers, Gas Lasers), Configuration (Fixed Beam, Moving Beam, Hybrid), Application (Cutting, Welding, Drilling, Marking and Engraving), End-user Industry and Region – Global Forecast to 2029” The Laser Processing Industry Size is expected to reach USD 11.0 billion by 2029 from USD 6.8 billion in 2024, at a CAGR of 10.1% during 2024–2029. The significant growth factors associated with the Laser Processing Industry growth are the Surging demand for laser processing in medical applications, advancement of laser-based techniques compared with conventional material processing methods, Significant transition towards nanodevices and microdevices production, Rising demand for authentic and top-notch products.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=611

Browse 186 market data Tables and 78 Figures spread through 262 Pages and in-depth TOC on “Laser Processing Market by Laser Type (Solid Lasers, Liquid Lasers, Gas Lasers), Configuration (Fixed Beam, Moving Beam, Hybrid), Application (Cutting, Welding, Drilling, Marking and Engraving), End-user Industry and Region – Global Forecast to 2029”

View detailed Table of Content here – https://www.marketsandmarkets.com/Market-Reports/Laser-Cutting-Boring-and-Engraving-Machines-Market-611.html

Laser Processing Industry Segmentation

By Segment, Laser Processing Industry for Solid Lasers is projected to grow with a higher CAGR during the forecast period.

The Solid lasers play a crucial role in laser processing due to their unique characteristics, reliability, and suitability for various applications. The importance of these lasers in laser processing is evident across different industries where precision, efficiency, and versatility are essential. Solid lasers prevent the wastage of materials in the active medium and produce both continuous and pulsed output at a higher efficiency than He-Ne (Helium-Neon) and Argon lasers by about 2–3%.

By Segment, Laser Processing Industry for Moving Beam Configuration is to grow at the highest growth rate during the forecast period.

The movable configurations allow for dynamic adjustments to accommodate various workpieces and production requirements. The increased flexibility in directing the laser beam to different areas of the workpiece due to moving beam, is allowing for intricate and customizable patterns. This flexibility is especially advantageous in laser cutting and engraving applications, where precision is paramount. Moving beam configurations also offer higher speed and efficiency in covering larger areas than stationary setups, contributing to enhanced productivity. Moreover, the dynamic control over the laser beam’s movement allows for easy processing of complex shapes and varying geometries.

By Segment, Laser Processing Industry for Cutting Application holds the largest market share during the forecast period.

The market is segmented into various applications including cutting, welding, drilling, welding, marking & engraving, microprocessing, advanced processing, and others. The global rise in the cutting of both metals and non-metals has heightened the demand for high-powered lasers. Over recent years, lasers have garnered significant popularity not only in high-power applications but also in low power uses, including cutting plastics and paper. In the microelectronics sector, lasers have demonstrated their cost-effective prowess as a method for cutting wafers, ensuring the production of top-tier, high-quality products.

By Segment, Laser Processing Industry for Aerospace Sector is expected to grow at a highest CAGR during the forecast period.

Laser processing plays a crucial and multifaceted role in the aerospace industry, contributing to various aspects of manufacturing, maintenance, and research. Laser processing is widely favored in the aerospace industry for its exceptional precision, material versatility, and ability to handle complex geometries. The non-contact nature of laser systems ensures minimal material distortion, a critical factor in aerospace applications where precision and structural integrity are paramount. Aerospace components demand extremely high precision, and laser processing provides a level of accuracy that is often unparalleled. Laser cutting, welding, and drilling enable the production of intricate and complex components with tight tolerances.

Regional Analysis of Laser Processing Industry

By Region, Laser Processing Industry for North America is expected to grow at the highest growth rate during the forecast period.

North America consists of – the US, Canada and Mexico. The US is serving as the major contributor to the laser processing industry in this area. North America’s dominance in the laser processing industry is driven by region’s commitment to advanced manufacturing and Industry 4.0 principles propels the integration of laser technologies, particularly in sectors like aerospace, defense, and medical device manufacturing. Laser processing plays a crucial role in automotive innovations, meeting fuel efficiency standards and advancing complex component manufacturing.

The report profiles key players such as Coherent Corp. (US), TRUMPF (Germany), Han’s Laser Technology Industry Group Co., Ltd (China), IPG Photonics Corporation (US), Jenoptik AG (Germany), and others.

Media Contact

Company Name: MarketsandMarkets™ Research Private Ltd.

Contact Person: Mr. Aashish Mehra

Email: Send Email

Phone: 18886006441

Address:630 Dundee Road Suite 430

City: Northbrook

State: IL 60062

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/Laser-Cutting-Boring-and-Engraving-Machines-Market-611.html