February 23, 2024 – Micro-One, an industry leader in environmental solutions, proudly announces the debut of its cutting-edge exhaust processing technologies aimed at reshaping how industries combat air quality issues. The company introduces a comprehensive range of advanced solutions, including the Selective Catalyst Reactor (SCR), Selected Non-Catalyst Reactor (SNCR), Semi-Dry Reactor (SDR), Dry Reactor (DR), Scrubber, Filter Dust Collector (BF), and Electric Dust Collector (ESP).

Micro-One’s DS E&E SCR Facilities target the reduction of nitrogen oxides (NOx) emissions through state-of-the-art Selective Catalytic Reduction (SCR) technology. Operating within a temperature range of 170~200℃, these facilities employ a low-temperature catalyst to efficiently convert NO into harmless N₂ and H₂O. The application of this breakthrough technology at the rear end of filter dust collectors in waste incineration facilities underscores Micro-One’s commitment to environmental sustainability.

Micro-One’s SNCR system utilizes a two-fluid nozzle to disperse urea water into the secondary combustion chamber at temperatures of 950℃±50℃. This advanced process decomposes and eliminates nitrogen oxides, ensuring a cleaner and safer environment while meeting stringent emission standards. This technology positions Micro-One as a frontrunner in the industry’s efforts towards sustainable emissions reduction.

Micro-One’s Semi-Dry Reactor (SDR) Facilities achieve remarkable removal efficiency by leveraging a small lime slurry [Ca(OH)] and second-rate spray nozzle. This innovative approach effectively addresses harmful acid gases (HCl, SOx) while minimizing wastewater generation. The SDR Facilities exemplify Micro-One’s commitment to sustainable practices within Korean industries.

Micro-One’s Dry Reactor (DR) technology is engineered to combat environmental challenges by efficiently removing pollutants, with a particular focus on harmful acid gas removal. Utilizing a small lime slurry and a second-rate spray nozzle, the DR system exemplifies Micro-One’s dedication to balancing industrial growth with environmental stewardship.

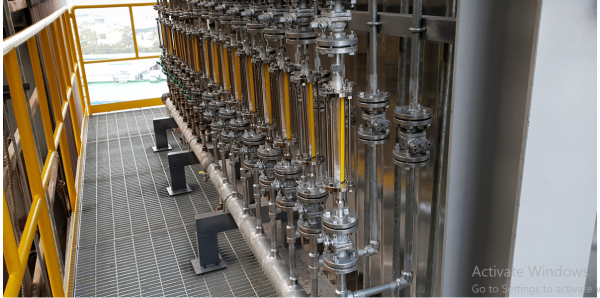

Micro-One’s DS E&E Scrubber Facility is a versatile device designed to effectively remove acidic gas and particulate matter. By employing various plastic fillings and absorbents such as NaOH, this vertical tower enhances gas-liquid contact area, ensuring exceptional decontamination efficiency. Widely used for water-soluble hazardous gas treatment and dust control, the scrubber stands as a vital solution for industries prioritizing effective gas treatment.

Micro-One’s Filter Dust Collector (BF) and Electric Dust Collector (ESP) further demonstrate the company’s commitment to meeting and surpassing stringent environmental standards. These collectors efficiently capture particulate matter, enabling industries to maintain optimal air quality while complying with regulatory requirements.

Micro-One remains at the forefront of providing innovative exhaust processing solutions, aligning industries with sustainable practices and environmental responsibility. With a focus on reducing environmental impact, Micro-One’s state-of-the-art technologies are poised to redefine global air quality management.

For more information about Micro-One and its groundbreaking technologies, please visit their website.

For media inquiries, please contact:

Media Contact Name: Andy Hong

Email: info@micro-one.kr

About Micro-One

Micro-One is a pioneering environmental solutions company dedicated to developing advanced technologies for exhaust processing. With a focus on sustainability and environmental responsibility, Micro-One’s innovative solutions are designed to address the challenges of air quality management in industries worldwide.

Media Contact

Company Name: Micro One

Contact Person: Andy Hong

Email: Send Email

Country: South Korea

Website: www.micro-one.kr/?page_id=596&lang=en