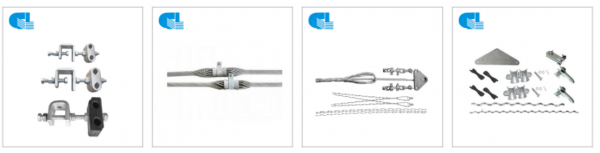

Install the fittings and accessories in 48 hours after tightening the cables in the tension section to avoid unnecessary damage to the fibers caused by overfatigue of the cable, for the cable could be easily abraded or vibrates in the pulley. Fittings and accessories of OPGW usually include: tension clamp, suspension clamp, special earth wire, vibration damper, armor rods, downlead clamp, joint box and so on.

1. Installation of tension clamp

Tension clamp is the key hardware to install OPGW which not only fixes the cable on the pole and tower and affords much pressure but also grips the cable tightly while not exceeds the side pressure intensity of OPGW. Tension clamp is usually used in the termination tower, corner tower of over 15°, the cabling tower or pole tower of large altitude difference. The standard pre-stranding tension clamp is constituted of inner stranding wire, outer stranding wire, thimble, bolt, nut and so on.

Steps of installation:

A. Fix the hardware in the tower after the cable arc is adjusted with putt-off equipments.

B. Pull the outside stranding wire of tension set through heart-shaped loop of the transit hardware. Make the stranding wire parallel with the cable and mark the cable in the place of coloring on the wire.

C. Correspond the inside stranding wire with mark on the cable, and then, reel the first group of pre-stranding wire on the cable. Reel the other pre-stranding wires or insert the grounding flake by the coloring mark to ensure all the pre-stranding wires reeling together tightly and the ends are trim and well-proportioned. Prevent pre-stranding wire from transmutation by overexerting so as not to influence the distance of bolts.

D. Put the pre-stranding wire into the thimble and correspond the cross-section mark of outside stranding wire with the coloring earmark of inside stranding wire. And then, reel the outside stranding wire. Keep the space symmetrical no matter reel from one part or two parts.

2 Installation of suspension clamp

Pre-stranding suspension clamp is used to hang the cable in the lower, which is constituted of inside stranding wire, outside stranding wire, rubber clamp, alloy ingot crust, bolt, nut and gasket

Steps of installation:

A. Mark the suspension fixed point on the OPGW cable and reel the inside stranding wire from the middle part, which has been marked. Use hands not tools to reel the termination part after reeling all the inside stranding wires.

B. Put the center of the inside stranding wire to the center of rubber clamp and fixed with the insulted tape, And then, reel the outside stranding wire on the robber clamp along with the curve or insert the grounding Hake. Keep the space symmetrical and avoid intersecting.

C. Put the center of the crush to the center of the stranding wire end rip the bolt and fix it. And then connect with suspension staple, rip the bolt and hang on the tower.

3. Installation of vibration damper

Vibration damper is used to eliminate or loosen the vibration caused by all kinds of factors during OPGW operation so as to protect OPGW cable and prolong the life of the cable.

3.1 Installation number allocation principle:

The number of vibration damper is allocated according to the following principle: span≤250m: 2 sets; span: 250~500m (including 500m), 4 sets; span: 500~750m (including 750m), 6 sets; when the span is over 1000m, allocation plan should be changed according to line situation.

3.2 Installation position

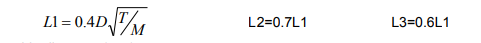

(1) Computational formula:

Computational formula:

D: cable diameter (mm)

T: cable annual average stress (kN), generally 20% RTS

M: cable unit weight (kg/km)

(2) Starting point of vibration damper installation: the starting point of L1 is the center line of suspension clamp and the center line of tension clamp thimble; the starting point of L2 is the center of the first vibration damper, the starting point of L3 is the center of the second vibration damper, and so on.

(3) The first vibration damper should be installed on the inner stranding wire of accessories, and others

are installed on special armor rods from second vibration damper.

4. Installation of earth wire

The earth wire is mainly used to supply access to short cut electricity when the OPGW is grounding. It is stranded by alloy wire and connected with accessories with parallel groove clamp or illustration and the other end is connected to tower grounding hole. The installation of earth wire should be aesthetic, with suitable length, without bend or twist. Connection points should have good contacts and keep unified in all lines.

5. Installation of downlead clamp, cable tray and joint box

Cable at the splicing point on the tower should be spliced after being lead to the ground. Along two sides of earth wire stand of the tower to the tower body and then lead along the inside of the tower body. Bending radius of the route where downlead passes through shouldn’t be less than 1m, and the minimum bending radius should be promised during operation, generally more than 0.5m. After the cable is lead to the ground, downlead clamp is used to fasten the cable on principle material or other material of the cable. Anchor ear type downlead clamp should be used when it is lead along concrete pole (such as converting station, power plant structure). Cable downlead should be straight and beautiful. Joint box and cable tray should be installed at suitable place on the tower, and about 8~10m above the datum surface of the tower. The installation should be firm and all the lines should be unified.

Media Contact

Company Name: Hunan GL Technology Co.,Ltd.

Contact Person: Media Relations

Email: Send Email

Phone: 0731-89722704

Country: China

Website: https://www.gl-fiber.com/