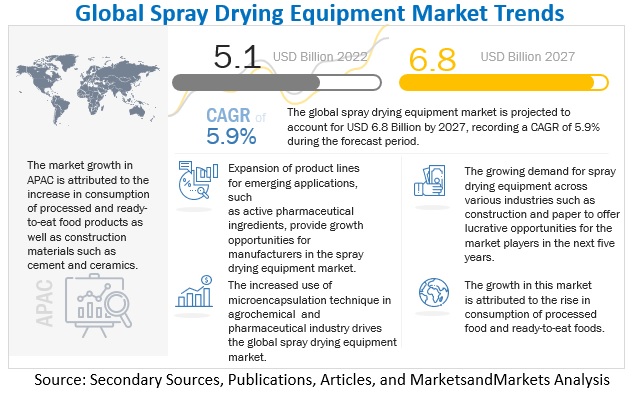

The spray drying equipment market is on the path to steady expansion, with a predicted CAGR of 5.9% in the next few years, propelling its market size to an impressive US$ 6.8 billion by 2027 from an estimated value of US$ 5.1 billion in 2022.This growth is driven by the increasing demand for processed food products and the rise in adoption of spray drying techniques in various industries, such as food, pharmaceuticals, and chemicals. With spray drying offering benefits like longer shelf life, reduced transportation costs, and enhanced product quality, this technology is gaining popularity among manufacturers worldwide. As a result, the market for spray drying equipment is poised to experience significant expansion in the coming years, providing opportunities for players in the industry to innovate and meet the demands of a growing market.

Spray drying equipment is a technology used to convert liquid or slurry-based feedstock into dry powder form. This equipment works by spraying the liquid feedstock into a hot gas stream, evaporating the liquid content and leaving behind the dry powder particles. Spray drying is commonly used in industries such as food, pharmaceuticals, chemicals, and ceramics to produce powdered products with desirable properties such as longer shelf life, improved stability, and increased solubility. Spray drying equipment includes components such as atomizers, dryers, air filters, and cyclones, among others. The market for spray drying equipment is on a steady rise, driven by the increasing demand for processed food products and the adoption of spray drying techniques in various industries.

Spray Drying Equipment Market Opportunities: Innovative product development and application in the pharmaceuticals and ceramic industries

Spray drying is one of the most widely used technologies in pharmaceuticals today, primarily to precisely convert a liquid feed into powder while maintaining the active ingredient’s purity, morphology, and stability. The most recent spray drying equipment market innovations have expanded the scope of spray-drying techniques in the pharmaceutical industry. One of the new areas of spray drying application is nasal drug delivery. The primary goal of nasal drug delivery is to deposit drug particles in the targeted tissues. A significantly small particle size of less than five micrometers in aerodynamic diameter is required for pulmonary applications of dry powders. Spray drying is a particle engineering technique which makes it possible to address specific needs and design particles accordingly and formulate sensitive APIs such as proteins or peptides.

The constant innovations in the field of spray drying, applications in bioceramics and biodegradable polymer industries are a key factor that is projected to create potential growth opportunities for global spray drying players in the coming years.

Challenges : Infrastructural challenges in developing countries

The saturated markets of developed countries encourage spray drying equipment manufacturers to look for untapped markets and new consumer bases. This necessitates significant investments in various aspects of business expansion, especially the establishment of new facilities in developing countries. Aside from internal facility investments, manufacturers must also spend more on the development of efficient supply chain management and the storage of raw materials and finished goods. Although low raw material and labor costs benefit businesses, the investment costs for infrastructure development pose a significant challenge.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=229851536

By application, pharmaceuticals lead the application segment due to their versatility

The spray drying process in the pharmaceutical industry involves continuous production while maintaining consistency in quality. Some pharmaceutical products are produced in crystal form which is difficult to use. Crystalline products do not dissolve easily in water and are absorbed slowly. Therefore, they currently witness low demand due to their bioavailability. Spray dryers dry the crystal compound once it has been dissolved in water for easier absorption. Drugs that are offered in their crystal forms are difficult for the body to use. Therefore, spray dryers make them more readily available and usable for the body. Spray drying can offer commercial and medical advantages with encapsulation as it helps in providing particles with the ability to be controlled in a time-release pattern. The substance is spray-dried and then compressed into a capsule form. The prolonged release of antibiotics allows a reduction in the dosage or concentration and can be effective when treating chronic illnesses.

Another major advantage offered by the spray-dried processing of medicines is that the process used to develop spray-dried products helps reduce vitamin and mineral content loss.

The most recent application of spray dryers in the pharmaceutical industry is witnessed in drug inhalation. Some important drugs that are to be administered through inhalation require the particle size to be maintained at the micro-level. Spray dryers offer the manufacturers to modify the particle size as per their requirements. This technology is expensive and, at present, is used at smaller production scales. The cost of commercially producing directly inhaled drugs is being reviewed so that their overall costs can be reduced.

The Asia Pacific region is projected to be the fastest-growing market for spray drying equipment

China and Japan accounted for a major market share in the Asia Pacific region. The growth potential of the infant formula and baby food markets in countries such as China, Japan, and India have resulted in an increase in demand for spray drying equipment.

In recent years, the Asia Pacific food encapsulation market has grown significantly. Encapsulation is used in food, dietary supplements, functional food, and other products. The rise in consumer demand for nutritional products is attributed to the markets expansion. As the spray drying process is widely used in food encapsulation techniques, the Asia Pacific spray drying equipment market is expected to expand.

Top Companies in the Spray Drying Equipment Market

The Major Players are GEA Group (Germany), SPX Flow (US), Shandong Tianli Drying Technology and Equipment (China), Büchi Labortechnik (Switzerland), European Spraydry Technologies (UK), Dedert Corporation (US), Changzhou Lemar Drying Engineering (China), Acmefil Engineering Systems Pvt. Ltd (India), New AVM Systech (India), Advanced Drying Systems (India), Labplant (UK), Swenson Technology Inc. (US), Yamato Scientific America (US), Tetra Pak International S.A (Switzerland), G Larsson Starch Technology Ab (Sweden).

GEA Group develops and produces process technology and equipment for various industries such as food, pharmaceuticals, and chemicals. Engineering solutions offered by GEA range from single pieces of equipment to complete plants. The spray dryers offered by GEA cater to several food & beverage applications. GEA operates in over 60 countries across North America, North & Central Europe, DACH & Eastern Europe, Latin America, Western Europe, Middle East & Africa, and Asia Pacific.

In February 2021, The GEA OptiPartner software solution and FSD dryer were ordered by Seagarden. The GEA FSD dryer went into production in Q3 of 2022. Fish-based collagen-peptide is a hydrolyzed form of collagen extracted from wild cod skins that is used in the food, beverage, and cosmetics industries.

SPX FLOW is one of the leading global suppliers of highly specialized engineering solutions and equipment. It has operations in more than 35 countries and sales in over 150 countries across the globe. The company particularly serves the food, beverage, oil & gas, power generation (nuclear and conventional), chemical processing, compressed air, pharmaceutical, and mining markets globally. The product portfolio of this company includes pumps, valves, mixers, spray dryers, filters, air dryers, hydraulic tools, homogenizers, separators, and heat exchangers, along with related aftermarket parts and services.

In August 2022, SPX FLOW, Inc. announced a new collaboration with Flottweg. Both companies will be able to design, supply, install, and commission end-to-end plant-based process solutions for customers in the nutrition, health, food, and beverage industries as a result of the collaboration. SPX FLOW brings to the partnership superior expertise in process technologies such as mixing, blending, separation, heat treatment, fermentation, evaporation, spray drying, membranes, and homogenization.

BÜCHI Labortechnik is one of the leading technological solution providers, particularly in laboratory equipment and commercial production equipment, globally. The company offers laboratory evaporation, industrial evaporation, spray drying, and encapsulation technologies to serve the pharmaceuticals, chemicals, food & beverages, feed, environmental analysis, and academic institutions sectors. It operates in more than 100 countries and has offices in North America, Europe, Asia Pacific, and other regions.

Spray Drying Equipment Market Report Highlights:

Addition/Refinement in the market overview: Updated market-related drivers, restraints, and opportunities have been added to provide an in-depth overview of the market. Additional validated data give better insights into the current and future trends in the market.

Newly introduced trade data analysis: Additional trade data analysis for the market has been incorporated in the report. This gives a broader outline for clients with increasing exports and imports in a particular region and helps in the decision-making for prominent industry players. Regulatory framework and trade scenarios have been analyzed for every region covered in the study.

The company evaluation quadrant for both key players and start-up/SME players has been provided (with respect to 25 companies) according to the latest company developments. Key player strategies and revenue analysis of the top five market players have been included.

Schedule a call with our Analysts to discuss your business needs: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=229851536

About MarketsandMarkets™

MarketsandMarketsTM has been recognized as one of America’s best management consulting firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

Earlier this year, we made a formal transformation into one of America’s best management consulting firms as per a survey conducted by Forbes.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ‘GIVE Growth’ principle, we work with several Forbes Global 2000 B2B companies – helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

Media Contact

Company Name: MarketsandMarkets™ Research Private Ltd.

Contact Person: Mr. Aashish Mehra

Email: Send Email

Phone: 18886006441

Address:630 Dundee Road Suite 430

City: Northbrook

State: IL 60062

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/spray-drying-equipment-market-229851536.html