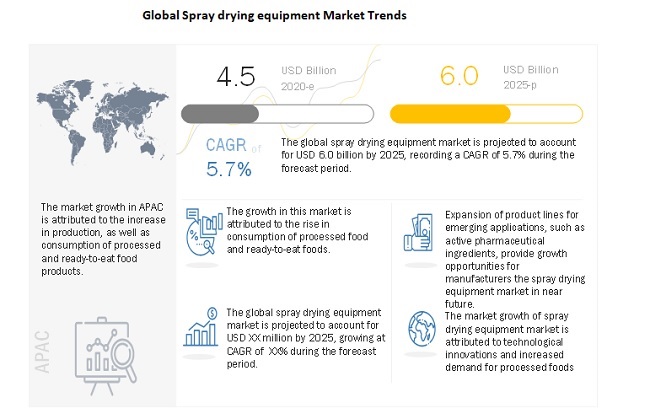

The global spray drying equipment market size is estimated at USD 4.5 billion in 2020 and is projected to grow at a CAGR of 5.7% to reach USD 6.0 billion by 2025. The market has a promising growth potential due to several factors, including the rising consumption of processed and RTE food products and technological innovation in the field of spray drying equipment.

COVID-19 Impact on the Global Spray drying equipment Market

The significant impact of the COVID-19 pandemic on the growth of the spray drying equipment market can be seen in its application areas. The major application areas of spray drying equipment include food & beverage, which witnessed a decrease in production in the first and second quarters of the year. However, the demand for these products is projected to increase majorly from the third quarter of 2020 due to the increase in demand for processed food products such as milk powders, ready-to-eat foods, and packaged foods. Another major sector that has been positively impacted is the pharmaceutical industry. The production of active pharmaceutical ingredients (API) and vaccines by spray drying equipment has been a constantly growing industry. The ability of manufacturers of spray drying equipment to produce fine, uniform micron size particles, as well as heat-sensitive vaccines, are two important factors that are projected to encourage the usage of spray drying equipment in the pharmaceutical industry.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=229851536

Driver: Increase in the consumption of processed and RTE Foods

Ready-to-eat (RTE) foods, as the name suggests, refer to that form of animal or plant-derived food products or a combination that can be offered to customers after being pre-washed, pre-cooked, processed, and frozen. Hence, they do not require elaborate processing by end-consumers before consumption; thus, saving their time and energy. According to the US Food Code, RTE foods, also known as ready meals, packed foods, or instant ready meals, is the largest segment globally in the overall conventional and non-conventional food industry due to higher consumer acceptance of food products. Further, changes in the lifestyle of consumers over the last decade due to rapid urbanization have led to a high demand for processed and ready-to-eat food products. A steep rise in dual-income levels, standards of living and the demand for convenience have also led to an increase in the busy lifestyles of consumers.

Thus, processed food manufacturers are opting for spray drying technologies. For instance, maltodextrin acts as a food additive in confectioneries and is widely used in sports and wellness products; maltodextrin is usually a spray-dried powder extracted from corn starch. The significant rise in demand for maltodextrin has led to an increase in the usage of spray dryers among food additive manufacturers and has reflected on the spray drying equipment market positively.

Opportunity: Increase in encapsulation application in food products

Spray drying technique has been widely used for drying heat-sensitive foods, pharmaceuticals, and other substances, as it witnesses rapid solvent evaporation from the droplets. Although it is most often considered a dehydration process, and spray drying can also be used as an encapsulation method when it entraps ‘active’ material within a protective matrix, which is essentially inert to the material being encapsulated. As compared to the other conventional microencapsulation techniques, it offers the advantage of producing microcapsules in a relatively simple, continuous processing operation.

Recently, the spray drying technique has been widely used for encapsulation techniques. Encapsulation using spray drying is highly preferred due to economic advantages as compared to the other encapsulation methods. Encapsulation of oils and food products using the spray drying technique is done to enhance the handling properties of products and improve oxidation stability by protecting the bioactive compounds.

On the basis of application, the food segment is projected to be the largest segment during the forecast period

The quick process of spray drying is largely used in the food industry, particularly in the dairy sector. Dairy products, such as milk, whey, cheese, buttermilk, butter, and dry creamers, are common items made using the spray drying technique. Instant coffee, dry creamers, and instant soups are also a few end-products that utilize spray-drying technology. It has a wide range of applications, which include food ingredients and the conversion of fruit & vegetable juices into instant mixes, instant coffee mixes, and drying of eggs and dairy products.

Asia Pacific is projected to be the fastest-growing region in the spray drying equipment market.

The Asia Pacific region is projected to be the fastest-growing market for spray drying equipment. India is one of the largest producers of milk in the world. Hence, the market for spray drying has been consistently witnessing growth in the Indian dairy processing equipment market. The market for infant formula and baby food has growth potential in countries such as China, Japan, and India. This would lead to an increase in demand for spray drying equipment.

Make an Inquiry: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=229851536

Key Market Players:

Many domestic and global players provide spray drying equipment to improve animal health and performance. Major manufacturers have their presence in the European and Nprth America countries. The key companies in the spray drying equipment market are GEA Group (Germany), SPX Flow (US), Shandong Tianli Drying Technology & Equipment (China), Buchi Labortechnik AG (Switzerland), and European SprayDry Technologies (UK). Various strategies, such as expansions, mergers & acquisitions, and new product launches, were adopted by the key companies to remain competitive in the dairy processing equipment market.

About MarketsandMarkets™

MarketsandMarkets™ provides quantified B2B research on 30,000 high growth niche opportunities/threats which will impact 70% to 80% of worldwide companies’ revenues. Currently servicing 7500 customers worldwide including 80% of global Fortune 1000 companies as clients. Almost 75,000 top officers across eight industries worldwide approach MarketsandMarkets™ for their painpoints around revenues decisions.

Our 850 fulltime analyst and SMEs at MarketsandMarkets™ are tracking global high growth markets following the “Growth Engagement Model – GEM”. The GEM aims at proactive collaboration with the clients to identify new opportunities, identify most important customers, write “Attack, avoid and defend” strategies, identify sources of incremental revenues for both the company and its competitors. MarketsandMarkets™ now coming up with 1,500 MicroQuadrants (Positioning top players across leaders, emerging companies, innovators, strategic players) annually in high growth emerging segments. MarketsandMarkets™ is determined to benefit more than 10,000 companies this year for their revenue planning and help them take their innovations/disruptions early to the market by providing them research ahead of the curve.

MarketsandMarkets’s flagship competitive intelligence and market research platform, “Knowledgestore” connects over 200,000 markets and entire value chains for deeper understanding of the unmet insights along with market sizing and forecasts of niche markets.

Media Contact

Company Name: MarketsandMarkets

Contact Person: Mr. Aashish Mehra

Email: Send Email

Phone: 18886006441

Address:630 Dundee Road Suite 430

City: Northbrook

State: IL 60062

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/spray-drying-equipment-market-229851536.html