Indoor sports floorings have unique requirements that differ from outdoor venues, particularly when it comes to the surfaces athletes train and compete on. Prefabricated rubber running tracks have emerged as an ideal solution for these indoor environments. NWT Sports, a leading provider of high-quality prefabricated rubber running tracks, offers products that cater specifically to the needs of indoor sports facilities. This article explores the numerous benefits of NWT Sports’ prefabricated rubber running tracks and why they are becoming the preferred choice for indoor sports facilities.

Superior Shock Absorption

One of the primary benefits of prefabricated rubber running tracks from NWT Sports is their superior shock absorption. Indoor sports facilities often host a variety of activities, and the floors need to accommodate the impact from running, jumping, and other high-intensity movements. The rubber composition of NWT Sports tracks absorbs shock effectively, reducing the strain on athletes’ joints and muscles. This minimizes the risk of injuries and allows athletes to train more comfortably and safely.

Durability and Longevity

NWT Sports’ prefabricated rubber tracks are engineered to withstand the rigors of continuous use. Indoor facilities can experience heavy foot traffic and intense usage patterns, and the durability of the track surface is crucial. The high-quality materials used in NWT Sports tracks ensure they remain intact and functional over long periods. These tracks resist wear and tear, maintaining their performance and appearance, which translates to lower maintenance costs and fewer replacements.

Enhanced Performance

Athletes perform better on surfaces that provide consistent traction and energy return. NWT Sports’ prefabricated rubber tracks offer a uniform surface that enhances grip and reduces slippage, even during high-speed sprints and quick directional changes. The energy return from the rubber surface helps athletes maintain speed and agility, contributing to improved performance during training and competitions.

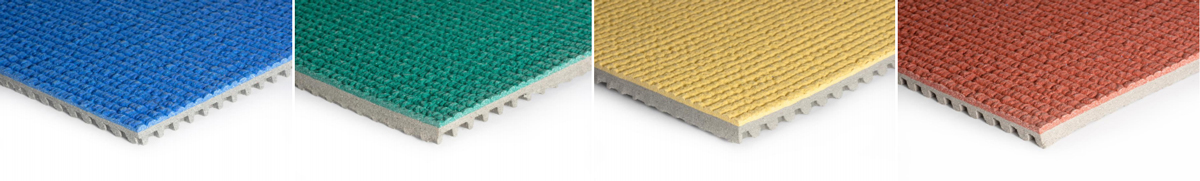

Prefabricated Rubber Running Track Color Card

Quick and Efficient Installation

Time is often a critical factor for indoor sports facilities looking to upgrade or install new surfaces. NWT Sports’ prefabricated rubber tracks are designed for quick and efficient installation. Prefabricated sections are manufactured in a controlled environment and then assembled on-site, reducing the installation time significantly compared to traditional track surfaces. This minimizes disruptions to the facility’s schedule, allowing for a swift transition to the new track.

Customizable Design

NWT Sports is committed to environmental sustainability, and their prefabricated rubber running tracks reflect this commitment. Made from recycled rubber materials, these tracks contribute to waste reduction and promote eco-friendly practices. Choosing NWT Sports tracks allows indoor sports facilities to support sustainability initiatives, which is increasingly important to athletes, patrons, and the broader community.

Noise Reduction

Indoor sports facilities often face challenges related to noise levels, particularly during high-energy activities. Prefabricated rubber tracks from NWT Sports help mitigate noise, providing a quieter environment. The rubber material absorbs sound, reducing the noise generated by foot traffic and athletic movements. This creates a more pleasant atmosphere for athletes, coaches, and spectators.

Eco-Friendly and Sustainable

The application of prefabricated rubber tracks in international competitions underscores their superior performance, durability, and environmental benefits. Brands like NWT Sports lead the way in providing high-quality track surfaces that meet the demands of global sports events. As the sports industry continues to evolve, the adoption of prefabricated rubber tracks is set to increase, driven by their proven advantages in enhancing athletic performance and promoting sustainability.

Maintenance and Care

Maintaining an indoor sports facility can be resource-intensive, but NWT Sports’ prefabricated rubber tracks simplify this process. These tracks are low-maintenance, requiring only regular cleaning to keep them in top condition. Their durable construction means they are resistant to common issues such as cracking, chipping, or fading, reducing the need for frequent repairs or replacements.

Conclusion

NWT Sports’ prefabricated rubber running tracks offer numerous benefits that make them the ideal choice for indoor sports facilities. Superior shock absorption, durability, enhanced performance, quick installation, customizable design, eco-friendliness, noise reduction, and low maintenance are just a few of the advantages these tracks provide. By choosing NWT Sports, indoor sports facilities can ensure they are providing athletes with the best possible training and competition environment, while also benefiting from a high-quality, sustainable, and cost-effective solution.

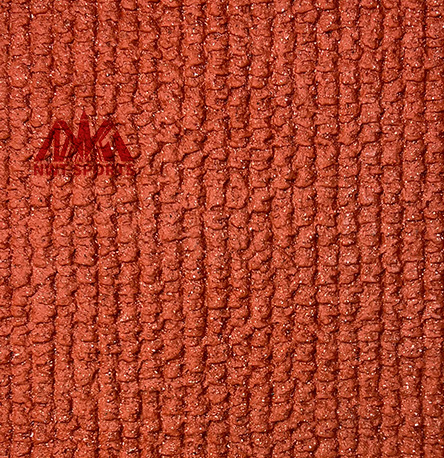

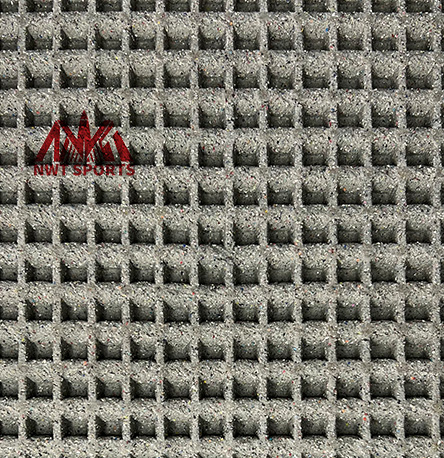

Prefabricated Rubber Running Track Details

Wear-resistant layer

Thickness: 4mm ±1mm

Honeycomb airbag structure

Approximately 8400 perforations per square meter

![]()

Elastic base layer

Thickness: 9mm ±1mm

Prefabricated Rubber Running Track Installation

1. The foundation should be smooth enough and without sand. Grinding and leveling it. Be sure it does not exceed ± 3mm when measured by 2m straightedges.

4. When materials arrive at the site, the appropriate placement location must be selected in advance to facilitate the next transportation operation.

7. Use a hair dryer to clean the surface of the foundation. The area to be scraped must be free of stones, oil and other debris that may affect the bonding.

10. After each 2-3 lines are laid, measurements and inspections should be made with reference to the construction line and material conditions, and the longitudinal joints of the coiled materials should always be on the construction line.

2. Use polyurethane-based adhesive to seal the surface of the foundation to seal the gaps in the asphalt concrete. Use adhesive or water-based base material to fill the low areas.

5. According to the daily construction usage, the incoming coiled materials are arranged in the corresponding areas, and the rolls are spread on the foundation surface.

8. When the adhesive is scraped and applied, the rolled rubber track can be unfolded according to the paving construction line, and the interface is slowly rolled and extruded to bond.

11. After the entire roll is fixed, transverse seam cutting is performed on the overlapped portion reserved when the roll is laid. Make sure there is enough adhesive on both sides of the transverse joints.3. On the repaired foundation surface, use the theodolite and steel ruler to locate the paving construction line of the rolled material, which serves as the indicator line for running track.

6. The adhesive with the prepared components must be fully stirred. Use a special stirring blade when stirring. The stirring time should not be less than 3 minutes.

9. On the surface of the bonded coil, use a special pusher to flatten the coil to eliminate air bubbles remaining during the bonding process between the coil and the foundation.

12. After confirming that the points are accurate, use a professional marking machine to spray the running track lane lines. Strictly refer to the exact points for spraying. The white lines drawn should be clear and crisp, even in thickness.

Media Contact

Company Name: NWT Sports Co., Ltd.

Email: Send Email

Address:No. 1-2, Industrial Park, Shuigaozhuang, Xinkou, Xiqing District

City: Tianjin

Country: China

Website: https://www.nwtsports.com/