Product Introduction

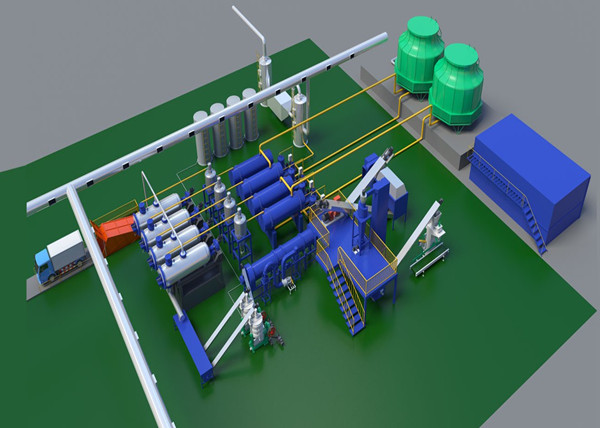

Poultry Waste Meat Meal Rendering Plant Feed Processing Machine is suitable for poultry, poultry waste, pig, cow, sheep, fish, feather, bone, blood, all animal waste. High efficiency, all the machine can be equipped by customers requirement, a complete production line or a simple one just depend on all customers choice.

Finally product will be meal and oil, the meal can be used for poultry feed, the oil will be used for industrial oil.

Raw Material Workflow

Pre-breaker System, Screw, Cook and Dry, Buffer, Press, Cooling, Mill, Automatic Packing

Waste Process Workflow

Waste Air Cooling, Spray and Washing, Flitter, High-energy Photon Oxidation, Discharge after reaching standard

Bin

The size and design of the bins will depend on the amount of material on the process in the subsequent plantand on the kind of material to be handled. We supply all kinds of bins. From small charging/dosing bins (2-5m³) to large storage bins of approximately 150-200m³. The manufacture can be of stainless steel, mild steel or a combination of both.

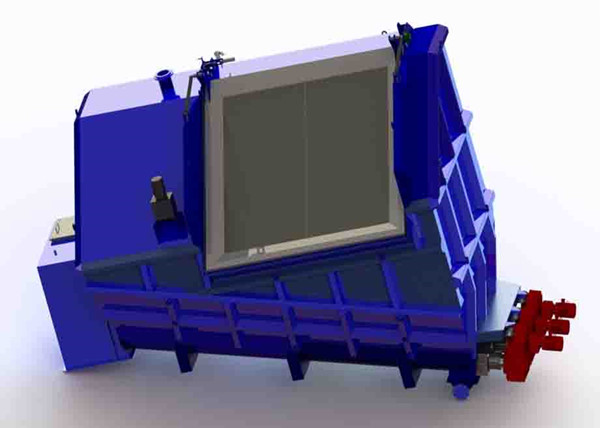

Pre-breaker

The Pre-breaker is especially designed or size reduction of complete carcasses of cattle, horses and pigs as well as all sorts of offal and bones from slaughterhouses,prior to the rendering process in the animal by-products industry.

Batch Cooker

The XZD batch cooker can be used for processing of the following animal by-products 1. Mixed meat offal and bones 2. Raw blood 3. Wet feathers 4. Mixed poultry offal 5. Pig, cow, sheep, etc.

|

Technical Specifications

|

Unit

|

BC5000

|

BC6500

|

BC8500

|

BC10000

|

BC16000

|

|

Dimension L

|

mm

|

5450

|

7100

|

7425

|

8400

|

9000

|

|

Dimension W

|

mm

|

2070

|

2070

|

2305

|

2305

|

2500

|

|

Dimension H

|

mm

|

1600

|

1600

|

1775

|

1775

|

2100

|

|

Designed Presssure Jacket

|

Bar

|

10

|

10

|

10

|

10

|

10

|

|

Designed Pressure Cooker

|

Bar

|

5

|

5

|

5

|

5

|

5

|

|

Heating Surface

|

m2

|

27

|

35

|

41

|

49

|

63

|

|

Power

|

KW

|

37

|

45

|

55

|

75

|

110

|

|

Shipping Weight

|

KG

|

12000

|

13500

|

19000

|

22000

|

36000

|

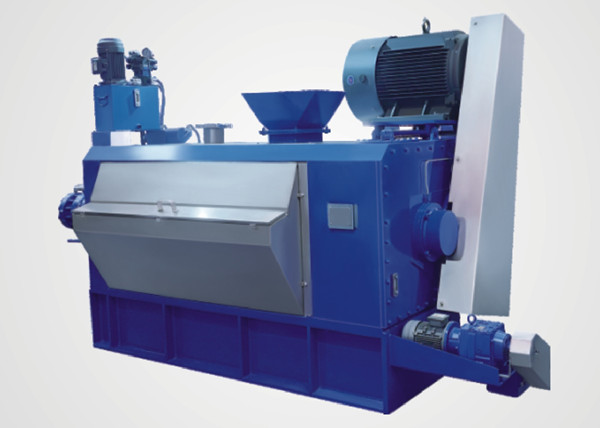

Oil Press

With thick steel plate. more durable. A variety of models, suitable for different processing capacity of customers. Handing large quantities, occupy a small workshop area. Small power consumption, easy to operation, management and! maintenance. Low residual oil press cake, good oil quality, the processed cake is loose and not fragile.

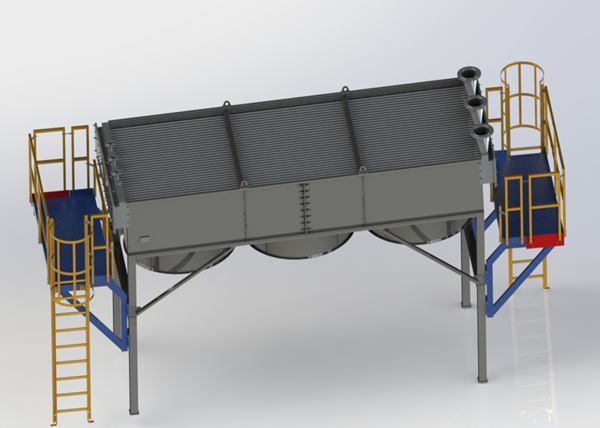

Air Condenser

The Air Cooled Condenser is designed for condensing the processing vapours emitted from cooking or drying of meat or fish by products. The condensed water can be recycled to other machine.

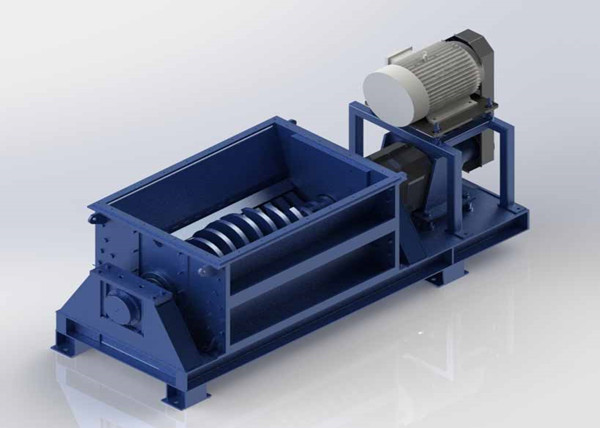

Screw Conveyor

Functions: get the material to a predetermined position.

Cooler

The quick water-flow type cooler will cool down the powder and granular mate rial. When the material gets cool, this mactiine will select out different size products.

Mill

The mill is used to reduce the particle size of greaves after fat extraction. The reduction in size required at this stage dependson whether the meal is used directly in compound feeds or it will be passed through a further stage of size reduction.

Automatic Packaging Machine

Feature: Automatic weighing, no material residual, easy to calculate the weight. bag quantity, total capacity. Fast packing speed and high-accuracy. Easy to operate and maintain.

Media Contact

Company Name: Shandong Sensitar Machinery Manufacturing Co., Ltd.

Email: Send Email

Phone: +86-536-6053990

Country: China

Website: https://www.sensitarrendering.com/