The ordinary process of tea manufacturing

The process of tea manufacturing typically involves several steps, which may vary depending on the type of tea being produced. Here are the general steps involved in the manufacture of black tea:

1. Withering: Freshly plucked tea leaves are spread out on large trays or racks and left to wilt for several hours. This allows excess moisture to evaporate and makes the leaves more pliable.

2. Rolling: The withered leaves are rolled and crushed to break their cell walls and release enzymes that initiate fermentation. This process also helps to shape the leaves and create a more uniform texture.

3. Fermentation: The rolled leaves are spread out on trays and left to ferment for several hours. During this time, the enzymes in the leaves interact with oxygen and begin to change the chemical composition of the leaves, turning them from green to brown.

4. Drying: Once the desired level of fermentation is achieved, the leaves are dried to halt the fermentation process and preserve their flavor and aroma. This is typically done in large ovens or with hot air blowers.

5. Sorting: The dried leaves are sorted based on their size and quality. This is typically done with sieves or screens that separate the leaves into different grades.

6. Packaging: Finally, the sorted leaves are packaged in airtight containers to preserve their freshness and flavor. They are typically shipped to distributors or retailers who sell them to consumers.

Different types of tea, such as green tea or oolong tea, may involve slightly different processes. For example, green tea is typically not fermented but instead heated to stop enzyme activity and maintain its green color. Oolong tea is partially fermented, giving it a unique flavor and aroma profile.

Dehumidification in the process of tea manufacturing, packaging and storing

Dehumidification is an important aspect of tea manufacturing, packaging, and storing. Tea leaves are hygroscopic, which means they easily absorb moisture from the air. The optimum recommended condition of tea leaves during blending, storage, and packaging is 30 to 35% RH at ambient temperature. Excessive moisture can lead to mold growth, oxidation, and degradation of flavor and aroma in tea leaves. Therefore, maintaining the right level of humidity is crucial for ensuring the quality and freshness of the tea. Here’s how dehumidification is used in each stage of the tea process:

Dehumidifiers for Tea Manufacturing

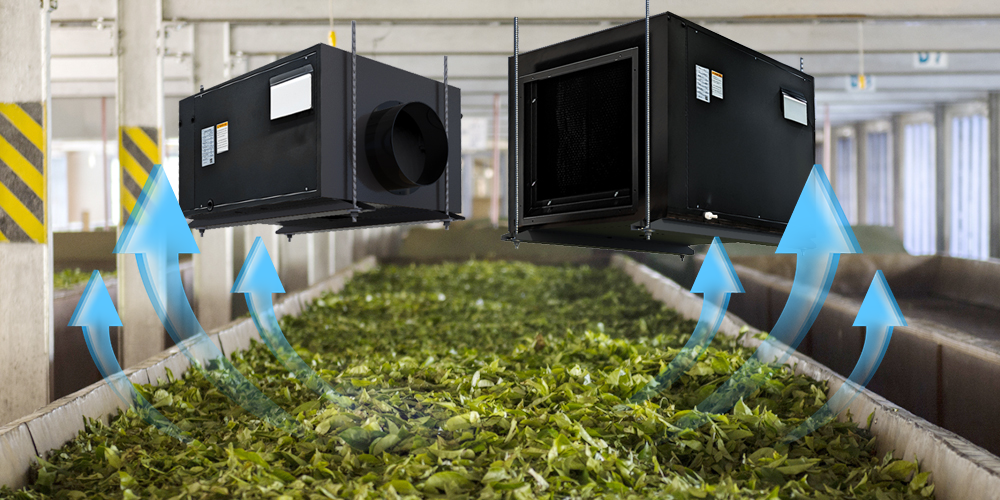

During the withering stage, tea leaves lose moisture, which is essential for the fermentation process. However, excessive moisture can lead to mold growth and spoilage. Dehumidifiers are used to regulate humidity levels and prevent excess moisture in the air. This ensures that tea leaves are properly withered without compromising their quality.

Dehumidifiers for Tea Packaging

Tea is packaged in airtight containers to prevent exposure to air and moisture. However, even a small amount of moisture can cause tea leaves to spoil. Therefore, it’s important to ensure that the humidity level in the packaging area is low. A ceiling hung dehumidifier is used to maintain low humidity levels, which helps to prevent mold growth and preserve the freshness of the tea.

Dehumidifiers for Tea Storing

Tea should be stored in a cool, dry place to prevent degradation of flavor and aroma. However, even in a cool place, humidity can cause tea leaves to absorb moisture, which can affect their quality. A ceiling mounted dehumidifier is used to maintain low humidity levels in tea storage areas, which helps to prevent moisture buildup and maintain the quality and freshness of tea over time.

In summary, dehumidification is an important aspect of tea manufacturing, packaging, and storing. It helps to regulate humidity levels and prevent moisture buildup, which can compromise the quality and freshness of tea.

Media Contact

Company Name: Zhejiang Preair Electrical Appliance Industry Co., Ltd.

Email: Send Email

Country: China

Website: https://www.preair.com/