Metallocene Polyethylene (mPE)

Properties:

mPE is a type of polyethylene that is produced using metallocene catalysts. It is known for its superior properties compared to conventional polyethylene, including:

– Improved strength and toughness

– Enhanced clarity and transparency

– Better processability and flow characteristics

– Tailored molecular weight distribution for specific applications

Applications:

mPE has a wide range of applications due to its unique properties:

– Packaging films for food, medical, and industrial products

– Agriculture, such as silage wrap and greenhouse films

– Consumer goods, including toys and household items

– Automotive parts, such as fuel tanks and under-the-hood components

– Protective coatings and adhesives

Metallocene Polypropylene (mPP)

Properties:

mPP is a type of polypropylene that is also produced using metallocene catalysts. It offers several advantages over conventional polypropylene:

– Enhanced mechanical properties, such as tensile strength and impact resistance

– Improved heat resistance and chemical stability

– Better control over crystallinity, leading to a range of properties from rigid to flexible

– Tailored molecular structures for specific end-use applications

Applications:

mPP is used in a variety of applications due to its improved properties:

– Automotive industry for lightweight components and interior parts

– Textile industry for high-strength fibers

– Medical devices and packaging

– Consumer goods, such as appliances and containers

– Building and construction materials

PFSA-free PPA Masterbatches in mPE and mPP Production

Enhanced Polymerization Process:

The use of PFSA-free PPA masterbatches in the production of mPE and mPP can significantly enhance the polymerization process. These masterbatches can improve the dispersion and distribution of the metallocene catalyst, leading to a more controlled polymerization and better control over the polymer’s molecular structure.

Increased Process Efficiency:

The incorporation of PFSA-free PPA masterbatches can lead to increased process efficiency in the production of mPE and mPP. These masterbatches can act as processing aids, reducing the viscosity of the polymer melt and improving flow properties. This can result in faster production rates, lower energy consumption, and reduced manufacturing costs.

Sustainability and Environmental Impact:

The use of PFSA-free PPA masterbatches in mPE and mPP production aligns with the growing demand for sustainable materials. By avoiding the use of PFSA compounds, which are known to be persistent in the environment, the petrochemical industry can take steps towards more environmentally friendly practices.

Market Opportunities:

The market for mPE and mPP is growing, driven by the demand for high-performance polymers with improved properties and sustainability. The use of PFSA-free PPA masterbatches in their production opens up new market opportunities for both the masterbatch suppliers and the end-users of these polymers.

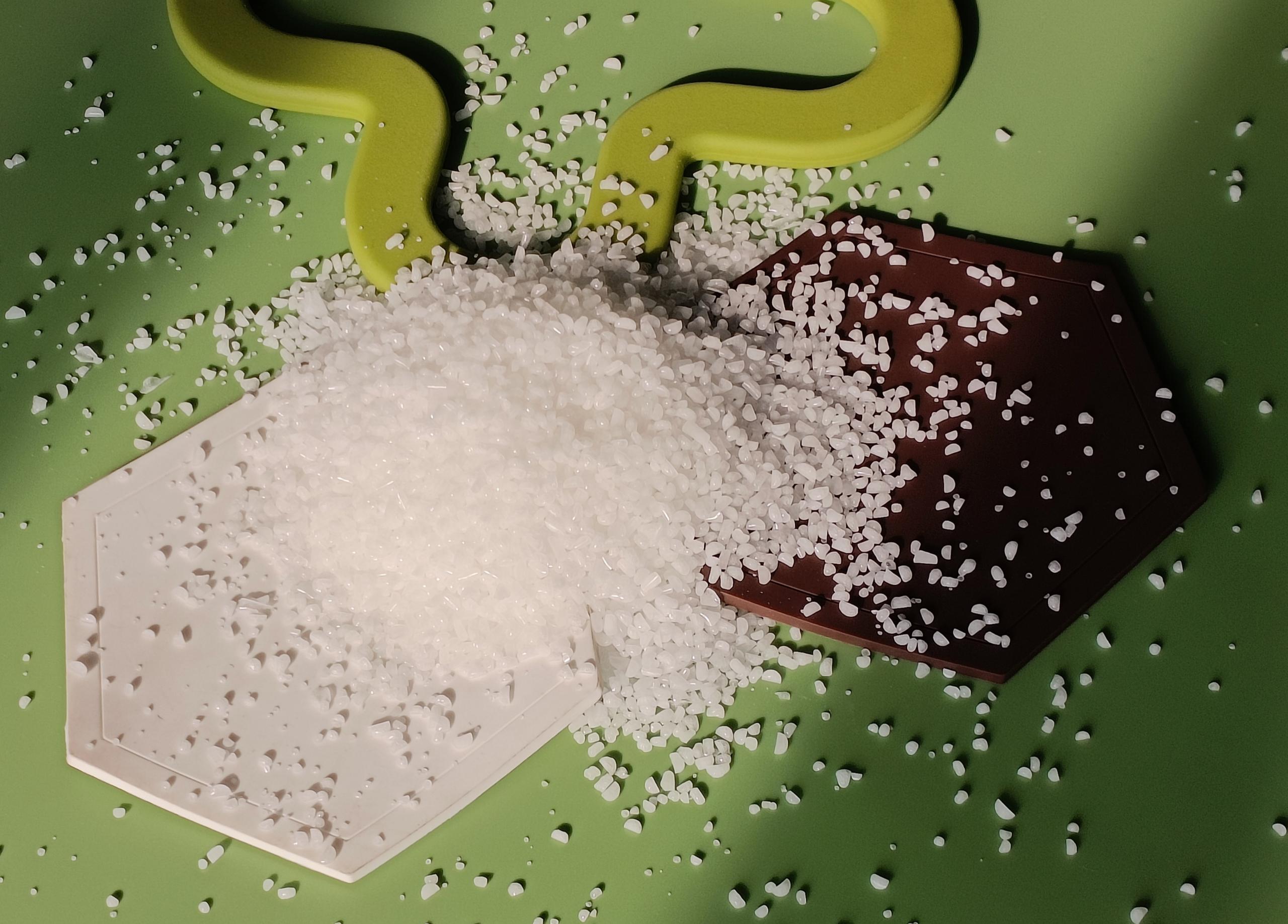

SILIKE SILIMER series PFAS-free PPA masterbatches, Options for replacing fluorinated PPA masterbatch

SILIME Fluorine-free PPA masterbatch is a PFAS-free polymer processing aid (PPA) introduced by Silicone. This product is a perfect substitute for fluorine-based PPA processing aids. Adding a small amount of SILIKE SILIMER 9200, SILIKE SILIMER 5090, SILIKE SILIMER 9300 ect… can effectively improve resin fluidity, processability, and lubricity and surface properties during plastic extrusion, eliminate melt rupture, improve wear resistance, reduce the coefficient of friction, and improve production and product quality while being environmentally friendly and safe.

The PFAS-free polymer processing aids (PPAs) introduced by SILIKE not only comply with the draft PFAS restriction made public by ECHA, but also provide a safe and reliable alternative for customers.

SILIKE PFAS-free PPA masterbatch has a wide range of applications, not only in the petrochemical industry, mPP, mPE, etc., but also in wires and cables, films, tubes, masterbatches and so on.

Conclusion: The Future of mPE and mPP with PFSA-free PPA Masterbatches

The integration of PFSA-free PPA masterbatches into the production of metallocene-based polymers such as mPE and mPP represents a significant advancement in the petrochemical industry. SILIE SILIMER series PFSA-free PPA masterbatches not only contribute to the improved performance and customization of the polymers but also align with the industry’s move towards more sustainable and environmentally friendly practices. As research and development continue, the potential applications and benefits of PFSA-free PPA masterbatches in mPE and mPP production are expected to expand, offering exciting prospects for the future of polymer technology.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn

website: www.siliketech.com to learn more.

Media Contact

Company Name: Chengdu Silike Technology Co.,Ltd.

Contact Person: Silike Technology

Email: Send Email

Country: China

Website: https://www.siliketech.com/