When it comes to finding the best material for a wide range of applications, UHMWPE (Ultra High Molecular Weight Polyethylene) sheet stands out as the ultimate choice. Its unbeatable combination of physical and chemical properties make it a versatile and reliable solution across various industries. This blog post will explore the key features and benefits of UHMWPE sheet, and why it has gained such popularity among engineers and manufacturers worldwide.

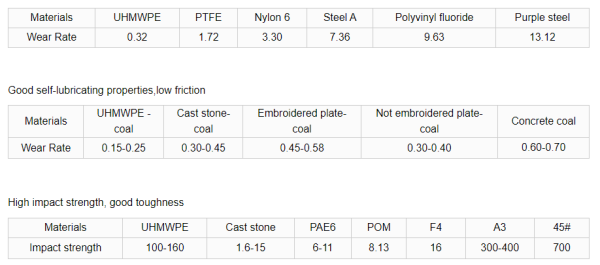

1. Wear Resistance – One of the outstanding characteristics of UHMWPE sheet is its exceptional wear resistance. In fact, it ranks first among all plastics in this aspect. It is eight times more wear-resistant than ordinary carbon steel, making it an ideal choice for applications that involve constant friction and abrasion. Even in the most demanding conditions, UHMWPE sheet will maintain its integrity and prolong the life of your equipment.

2. Excellent Impact Strength – UHMWPE sheet exhibits remarkable impact strength, six times greater than that of ABS (Acrylonitrile Butadiene Styrene) – a commonly used engineering plastic. This property is particularly valuable in low-temperature environments where other materials tend to become brittle. With UHMWPE sheet, you can rest assured that your equipment will withstand heavy impacts and maintain its structural integrity.

3. Strong Corrosion Resistance – Another notable property of UHMWPE sheet is its strong resistance to corrosion. Unlike metals that can rust or corrode, UHMWPE sheet remains unaffected by various chemicals, acids, and alkalis. This makes it an excellent choice for applications where exposure to corrosive substances is inevitable, such as chemical processing, wastewater treatment, and marine environments.

4. Self-lubricating – UHMWPE sheet has a unique self-lubricating property, allowing it to work smoothly and reduce friction without the need for additional lubricants. This feature not only improves efficiency but also minimizes maintenance requirements, as there is no need to constantly reapply lubricants. The self-lubricating property of UHMWPE sheet ensures reliable performance and extends the lifespan of your equipment.

5. Low Temperature Resistance – UHMWPE sheet offers exceptional resistance to low temperatures. It can withstand extremely cold environments, with the lowest temperature tolerance reaching as low as -170 degrees Celsius. This makes it an ideal choice for applications in freezing conditions, such as food processing, cold storage, and polar exploration.

6. Anti-aging – UHMWPE sheet exhibits excellent resistance to aging. Even under normal sunlight conditions, it can maintain its integrity and performance for up to 50 years without showing signs of aging or degradation. This exceptional durability makes UHMWPE sheet a cost-effective and reliable long-term solution for various applications.

7. Safe, Tasteless, Non-toxic – UHMWPE sheet is a safe and non-toxic material. It is widely used in industries that require strict hygiene and safety standards, such as food processing, pharmaceuticals, and medical devices. Furthermore, UHMWPE sheet is tasteless, ensuring that it does not affect the quality or taste of food products.

In conclusion, UHMWPE sheet offers a range of exceptional properties that make it the ultimate plastic solution for various applications. Its wear resistance, excellent impact strength, strong corrosion resistance, self-lubricating capability, low temperature resistance, anti-aging properties, and safety features make it a top choice for engineers and manufacturers. Whether you need a material for heavy-duty machinery, intricate components, or hygienic environments, UHMWPE sheet will exceed your expectations. Invest in UHMWPE sheet today and experience the unparalleled benefits it offers.

The main performance comparison

High abrasion resistance

Media Contact

Company Name: Tianjin Beyond Technology Developing Co., Ltd.

Email: Send Email

Address:Tianjin Free Trade Test Area (Central Business District)

City: Tianjin

Country: China

Website: https://www.bydplastics.com/