Vapor deposition is a technique for applying thin films or coatings by converting materials into vapor and depositing them onto surfaces. It includes Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). Rising demand comes from semiconductors, solar panels, aerospace, and medical devices, driven by advanced electronics, renewable energy adoption, and high-performance coatings. With ongoing innovations, the market is set for steady growth. MarketsandMarkets projects that the global vapor deposition market will grow from USD 42.6 billion in 2023 to USD 66.1 billion by 2028, at a CAGR of 9.2%, during the forecast period. The vapor deposition market is experiencing a dynamic evolution, driven by a series of prominent trends that are reshaping the landscape of industrial manufacturing. The research report provides access to critical information such as vapor deposition market growth drivers, market growth restraints, current market trends, the market’s economic and financial structure, and other key market details.

The vapor deposition market is experiencing a dynamic evolution, driven by a series of prominent trends that are reshaping the landscape of industrial manufacturing. One of the most striking trends is the increasing integration of automation and digitization into vapor deposition processes. As industries strive for precision and efficiency, automation technologies are being employed to enhance control, reduce human error, and optimize coating consistency. Moreover, the growing emphasis on sustainability has led to the development of environmentally friendly deposition techniques and the utilization of eco-conscious materials, aligning with global efforts toward greener practices.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=151839918

CVD to dominate the global vapor deposition market during the forecast period.

The vapor deposition industry has been segmented based on technology as physical vapor deposition and chemical vapor deposition, which is further segmented into electron beam evaporation, magnetron sputtering, cathodic arc deposition, atmospheric pressure CVD, low pressure CVD, metal organic CVD, and plasma enhanced CVD, and others. The CVD segment accounted for the larger share of the market in 2022. The vapor deposition market is witnessing a surge in demand for complex, multi-functional coatings that offer enhanced performance characteristics. Industries are seeking coatings with superior wear resistance, thermal stability, and electrical conductivity, propelling research, and innovation in material science. Furthermore, the trend towards miniaturization in electronics and the demand for advanced microelectronics have fueled the exploration of nanoscale coatings, opening doors to unprecedented applications.

By End-use industry, electronics and semiconductor segment to lead the global vapor deposition market during the forecast period

The market has been segmented based on End-use Industry into aerospace and defense, automotive, electronics and semiconductor, energy and power, medical and healthcare, packaging, optics and optoelectronics, cutting tools and wear parts, and others. The electronics and semiconductor segment has emerged as a key driver in the market for vapor deposition market. The electronics and semiconductor End-use Industry segment leads the vapor deposition market. The relentless pursuit of miniaturization and precision within electronics necessitates cutting-edge techniques, making vapor deposition processes like chemical vapor deposition (CVD) indispensable. These methods offer unparalleled control over thin film deposition, crucial for crafting intricate structures in microelectronics. Beyond precision, vapor deposition empowers electronics with enhanced performance attributes, from tailored conductivity to optimal insulation.

Get a Sample Copy of This Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=151839918

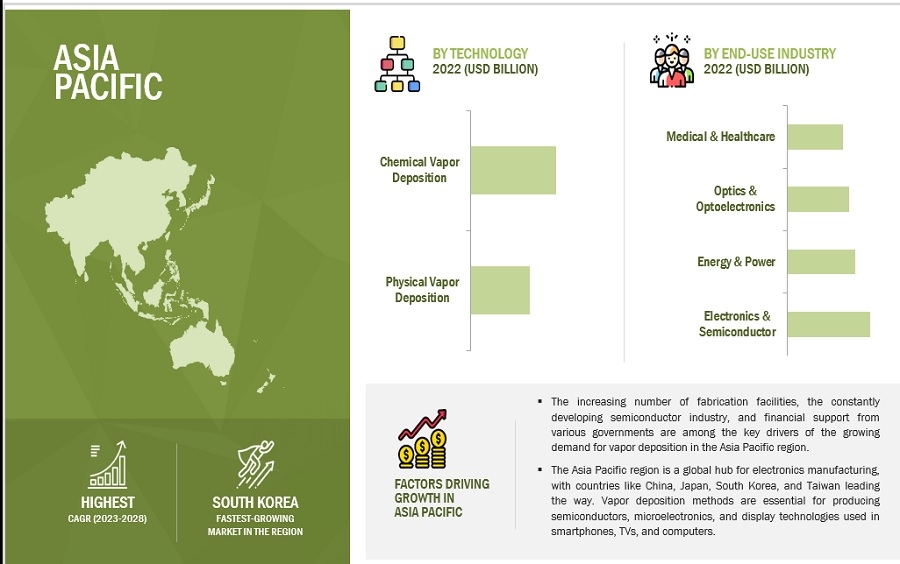

By region, Asia Pacific is expected to have the largest market size in the global vapor deposition market during the forecast period.

The Asia Pacific region has established itself as the largest and most influential market on the global stage for vapor deposition, with South Korea playing a pivotal role in this remarkable growth. A convergence of factors contributes to this dominance. Firstly, the region’s thriving electronics, semiconductor, and display industries have fueled an insatiable demand for vapor deposition technologies. As a hub for consumer electronics manufacturing, Asia Pacific’s appetite for precision, performance, and innovation aligns perfectly with the capabilities offered by vapor deposition processes. South Korea, in particular, stands out due to its world-renowned semiconductor and display manufacturing giants. The country’s investments in research, technological advancements, and strategic partnerships have propelled it to the forefront of vapor deposition innovation. With heavyweights like Samsung and LG leading the way, South Korea has contributed significantly to the evolution of vapor deposition techniques and their End-use Industrys, solidifying the Asia Pacific region’s dominance in the global market. The symbiotic relationship between Asia Pacific’s burgeoning industries and South Korea’s technological prowess continues to drive the vapor deposition market’s growth, shaping the future of multiple sectors and setting new industry benchmarks.

As semiconductor manufacturers continue to follow Moore’s Law, which predicts the doubling of transistors on a chip every two years, vapor deposition plays a crucial role in enabling the production of ever smaller and more powerful semiconductor devices. The thin films produced through vapor deposition provide the necessary insulation and conductivity for densely packed circuitry. Furthermore, emerging technologies like flexible electronics, organic electronics, and printed electronics rely heavily on vapor deposition for depositing functional layers onto flexible substrates. These applications have immense potential in areas such as wearable devices, flexible displays, and sensors.

Applied Materials, Inc. is a leading provider of manufacturing equipment, services, and software primarily serving the semiconductor, display, and related industries. The company is organized into four main segments: Semiconductor Systems, Applied Global Services, Display & Adjacent Markets, and Corporate and Other. The Semiconductor Systems segment is involved in the development, manufacturing, and sale of various equipment essential for producing semiconductor chips (integrated circuits or ICs). It encompasses a wide range of products and technologies, including Epitaxy, Ion Implantation, Oxidation/Nitridation, Rapid Thermal Processing, Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), Chemical Mechanical Planarization (CMP), Electrochemical Deposition, Atomic Layer Deposition (ALD), Etch, and Metrology and Inspection tools. The segment’s products, like centura, VIISta, endura, and others, are manufactured in different locations such as Singapore, Texas, Massachusetts, and Israel. In FY2022, the Semiconductor Systems segment contributed the majority of the company’s revenue, generating USD 18,797 million, which accounted for about 72.9% of the total. The Applied Global Services segment focuses on providing solutions aimed at optimizing the performance, productivity, and maintenance of equipment. These solutions enhance the efficiency and reliability of manufacturing processes in semiconductor and related industries.

Lam Research Corporation is primarily engaged in the production of wafer fabrication equipment and services to the semiconductor industry. Lam Research Corporation operates a network of facilities across Asia, Europe, the Middle East, and the US. The company has a diverse range of prominent brands, including ALTUS, Striker, SABRE, Syndion, VECTOR, Da Vinci, SPEED, SOLA, Kiyo, DV-Prime, Versys, EOS, Coronus, and Metryx. The company strategically categorizes its product offerings into three distinct segments: Deposition, Etch, and Clean processes and product families. Within its Deposition category, Lam Research specializes in producing layers of dielectric (insulating) and metal (conducting) materials that play a vital role in constructing semiconductor devices. Notably, the company’s ALTUS systems combine cutting-edge CVD and ALD technologies, facilitating the precise deposition of highly conformal films essential for advanced tungsten metallization applications. The company offers different products which include chemical vapor deposition (CVD), plasma-enhanced chemical vapor deposition (PECVD), electrochemical deposition (ECD), ultraviolet thermal processing (UVTP), and resist strip and surface preparation, as well as synergy cleaning products.

Inquire Before Buying: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=151839918

The company markets its products and services primarily to companies involved in the production of semiconductors in the U.S., Europe, Asia-Pacific, South Korea, and Japan. The company reported employee strength of nearly 18,700 people as of 2023 and competes globally with IHI Corporation (Japan), Kurt J Lesker (U.S.), Veeco Instruments Inc. (U.S.), and Jusung Engineering Co. Ltd. (South Korea).

Tokyo Electron Ltd. is a prominent company involved in the design, production, and marketing of semiconductor manufacturing equipment and industrial electronics products for the production of flat panel displays. The company operates through three main segments: Semiconductor Production Equipment (SPE), Flat Panel Display (FPD) Production Equipment, and Other Services. In the Semiconductor Production Equipment (SPE) segment, Tokyo Electron specializes in the creation, production, maintenance, and distribution of a range of equipment used in semiconductor manufacturing. This includes coaters/developers, plasma etch systems, thermal processing systems, single wafer deposition systems, cleaning systems, and wafer probers, among other essential tools.

The Flat Panel Display (FPD) Production Equipment segment is dedicated to manufacturing coater/developer machinery used in the production of flat panel displays, as well as plasma etching/ashing devices. It offers its range of CVD equipment under its semiconductor production equipment business and has presence across 16 countries with 77 locations.

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America’s best management consulting firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

Earlier this year, we made a formal transformation into one of America’s best management consulting firms as per a survey conducted by Forbes.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ‘GIVE Growth’ principle, we work with several Forbes Global 2000 B2B companies – helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

Media Contact

Company Name: MarketsandMarkets™ Research Private Ltd.

Contact Person: Mr. Rohan Salgarkar

Email: Send Email

Phone: 18886006441

Address:1615 South Congress Ave. Suite 103, Delray Beach, FL 33445

City: Florida

State: Florida

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/vapor-deposition-market-151839918.html