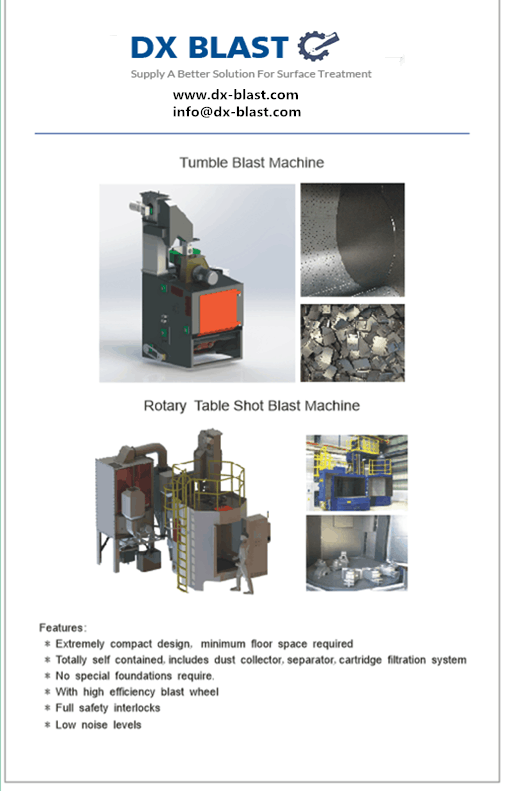

Rotary table shot blasting machines are widely used in foundry and automobile manufacturing industries. They have the characteristics of high production efficiency, good sealing effect, compact structure, convenient loading and unloading parts and high technical content. The rotary table shot blasting machine is mainly composed of the chamber body, the turntable, the transmission system, the separator, the elevator, the blasting device, the shot blasting device, etc., and a high-speed rotating shot blasting device is on the top of the chamber. The workpiece is projected in the best position, and the direct-connected curved blade head is used. The rotary table shot blasting machine has readjusted the position of the head on the basis of the original design. When the workpiece is turned out of the chamber with the turntable, people can directly see the cleaning Effect in order to proceed to the next step.

The transmission mechanism of the rotary table shot blasting machine is driven by the friction wheel by the cycloid pin wheel reducer. The rotary table shot blasting machine is frictionally driven with the turntable through a clutch mechanism to make the turntable rotate smoothly. When the workpiece is turned outside, it can be used to directly flip and adjust the cleaned workpiece. It can also be used to flip the clutch handle at any time according to the difference of the cleaned workpiece and the difficulty of loading and unloading the workpiece to separate the friction wheel from the turntable, that is, the turntable. Stop and adjust the workpiece, then change the handle position, and the turntable starts to rotate again; firstly, there is a certain angle between the blasting head of the rotary table shot blasting machine and the horizontal and vertical to facilitate the cleaning of the inner cavity of the workpiece; secondly, the support of the turntable is completely changed to facilitate maintenance, loading and unloading.

The transmission system drives the pill scraper to rotate, and the sand is sent to the lower part of the hoist through the flow pill tube, and then the hoist is lifted to the separator for separation. The intact projectile is used by the shot blasting device through the blast tube and the gate, and the projectile is broken. And dust enters other corresponding pipelines separately for secondary separation. It is mainly suitable for the production of surface cleaning of small and medium-sized workpieces. Equipment of this specification is suitable for engine connecting rods, gears, diaphragm springs, etc.

Features of Rotary Table Shot Blasting Machine:

1. The rotary table shot blasting machine has a high-speed rotating shot blasting device on the top of the chamber body to best project the workpiece, and as the workpiece moves out of the chamber body, the cleaning effect can be seen for the next work.

2. The transmission system rotates through the scraper to make the broken shot blasting machine steel shot and dust enter the corresponding pipes for the second separation.

Media Contact

Company Name: DX-BLAST CO., LTD.

Contact Person: Media Relations

Email: Send Email

Phone: +86-592-5185561

Country: China

Website: https://www.dx-blast.com/