Porous graphite revolutionizes SiC crystal growth by improving yield, reducing defects, and lowering production costs.

Introduction:

Porous graphite, also known as porous carbon or porous graphite materials, is a specially designed form of graphite featuring interconnected pore networks. This unique material offers superior performance in a range of applications, particularly in the silicon carbide (SiC) crystal growth process. By playing a pivotal role in balancing gas-phase components, isolating trace impurities, and regulating local temperatures, porous graphite significantly enhances the growth of high-quality SiC crystals.

The Critical Role of Porous Graphite in SiC Crystal Growth:

In the SiC crystal growth process, the use of porous graphite introduces several key advantages. It acts as a distribution hub, balancing gas flow and preventing contamination from minute impurities, all while reducing carbon encapsulation and physical particle interference. This results in a considerable increase in the crystal thickness without compromising crystal quality.

Key Benefits of Porous Graphite in SiC Crystal Growth:

- Higher Crystal Yield: With porous graphite, SiC substrates are grown with significantly fewer defects, resulting in a higher yield of 4H-SiC single crystals compared to traditional crystal growth methods. The reduction in multi-crystal formation ensures better overall quality and uniformity in the final products.

- Improved Thermal Regulation: Porous graphite enhances the thermal management of SiC crystal growth systems by reducing thermal gradients. This temperature uniformity ensures better control of the crystal growth environment, leading to reduced defects and a more efficient process.

- Reduced Defect Density: When using traditional crystal growth methods, SiC substrates often exhibit defects such as micro-pipes and etching pits. By integrating porous graphite into the process, micro-pipe density (MPD) and etching pit density (EPD) are significantly reduced. The MPD can drop from 6-7 EA/cm² to as low as 1-2 EA/cm², achieving up to a 6-fold improvement.

- Cost Reduction and Increased Competitiveness: The adoption of porous graphite helps reduce the procurement costs of SiC crystal growth components. Additionally, by improving crystal thickness and reducing defects, it allows for a more cost-effective production process and improved overall yield, giving companies a competitive edge in the semiconductor market.

The Advantages of Semicera’s Porous Graphite Materials:

- High Porosity: Up to 65% porosity, ensuring optimal thermal and chemical properties.

- Uniform Pore Distribution: Evenly distributed pores for consistent performance across batches.

- High Batch Stability: Reliable consistency across production batches for repeatable results.

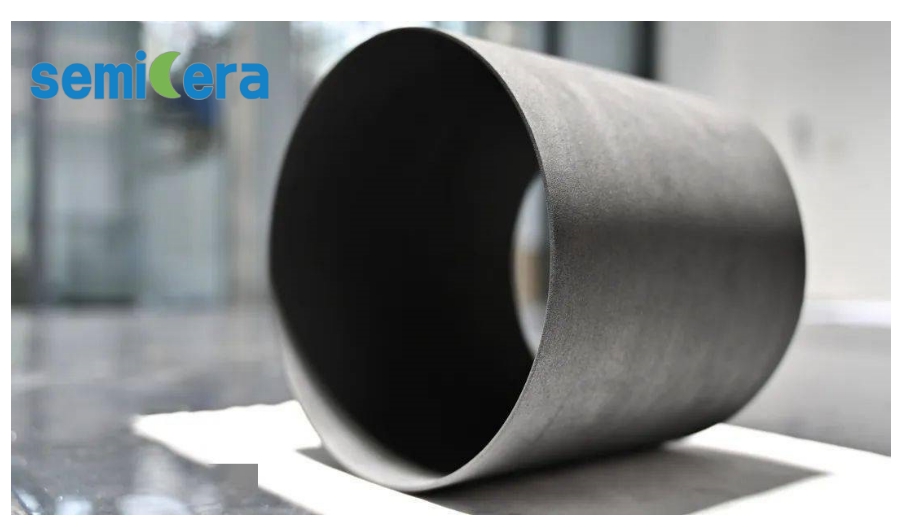

- Superior Strength and Processability: Strong enough to withstand demanding applications, with a machining tolerance that can achieve ultra-thin wall cylindrical shapes up to ≤1mm thickness.

Why Choose Semicera’s Porous Graphite for Your SiC Crystal Growth Needs?

As the semiconductor industry continues to evolve, Semicera is proud to offer cutting-edge porous graphite materials that support advanced SiC crystal growth. Our materials help improve product yield, reduce costs, and enhance overall manufacturing efficiency. Whether you’re aiming to increase SiC crystal thickness or optimize your process, Semicera’s porous graphite solutions provide the reliability and performance you need.

Get in Touch with Semicera Today!

For more information about how our porous graphite materials can revolutionize your SiC crystal growth process, please contact us:

Call: +86 0574 86503783, Email: sales05@semi-cera.com

Media Contact

Company Name: Semicera

Email: Send Email

Country: China

Website: https://www.semi-cera.com/