Industrial PCs are designed to cope with harsh industrial environments such as extreme temperatures, high humidity, dust and vibration, while regular PCs are designed for less demanding environments such as offices or homes.

Features of Industrial PCs:

Resistant to high and low temperatures: able to operate normally in extreme temperatures.Dust-proof design: Effectively prevents dust intrusion and ensures long-term stable operation.Vibration resistance: able to withstand vibration in industrial environments, reducing the risk of damage.High Humidity Adaptability: Reliable operation even in high humidity environments.Industrial PCs provide high reliability and stability in harsh industrial environments through their unique design and features, far exceeding the performance and application range of ordinary PCs.

Definition of Industrial PC (IPC) vs Personal Computer (PC):

Industrial PCs (IPCs) are computers designed for industrial applications with a high degree of durability and reliability to operate in extreme environments. They are commonly used in industrial automation, production control, data acquisition, and other applications that require high stability and extended operation.Personal computers (PCs) are computers designed for everyday use in the home and office, with a focus on user-friendliness and versatility, and are widely used for document processing, Internet browsing, multimedia entertainment and other routine computing tasks.

8 differences between industrial computers and personal computers

1. Durability: Industrial PCs are designed to operate in harsh environments such as extreme temperatures, dust, humidity and strong vibration conditions. They are often built with ruggedised enclosures and high levels of protection (e.g. IP65 rating) to ensure reliable operation even in harsh environments.

2. Performance: Industrial controllers are usually equipped with high-performance processors, high-capacity memory and fast storage to meet the demands of industrial tasks. They also support real-time operating systems and specialised software to improve processing efficiency and reliability.

3. Connectivity: Industrial controllers come with a wide range of connectivity options such as multiple Ethernet ports, serial ports, USB ports and dedicated industrial communication interfaces (e.g. CAN, Modbus, etc.) to suit the connectivity needs of a wide range of industrial devices and systems.

4. Cost: Due to the use of specialised, highly durable components and designs, industrial controllers typically cost more than a regular PC, but this investment can be offset by reduced maintenance and downtime, ultimately lowering the total cost of ownership.

5. Expandability: Industrial controllers are designed to be easily expandable and support a wide range of expansion cards and modules, allowing them to be upgraded and expanded in functionality as needed to adapt to changing industrial requirements.

6. Reliability: Industrial controllers are designed with redundancy, such as redundant power supplies and hot-swappable hard discs, to ensure high reliability and long life in critical applications.

7. Compatibility: Industrial controllers are usually compatible with a wide range of industrial standards and protocols, ensuring that they can be seamlessly integrated and operated in different industrial systems.

8. Long-term availability: The design and supply chain of industrial controllers ensures their long-term availability for applications that require stable operation over a long period of time, and can usually support a lifecycle of more than 10 years.

Characteristics of Personal PC and Industrial PC

Personal PC:general purpose, suitable for daily use and office applications, lower cost, user friendly, easy to operate and maintain.

Industrial PC:Rugged design, adaptable to harsh environments, with high reliability and long life, usually used in industrial and commercial areas of critical tasks, support a wide range of industrial protocols and interfaces.

Applications of Industrial PC

Applications in factories, production facilities and other industrial equipment:

Industrial PCs are commonly used for automated production line control, real-time data acquisition and monitoring to ensure efficient and stable operation of the production process.

Applications in medical equipment, public transport, logistics and warehousing and building management:

In medical equipment, industrial PCs are used for precision equipment control and data processing; in public transport systems, for scheduling and monitoring; and in logistics and warehouse management, for real-time tracking and inventory management.

Industrial PCs are used in manufacturing plants, outdoor installations and automation systems:

Industrial PCs are widely used in manufacturing factories for automation control and quality monitoring of production lines, and in outdoor installations for monitoring systems, traffic control systems, and so on.

Typical applications of industrial controllers in industrial automation, transport and critical infrastructure:

In industrial automation, industrial PCs are used for PLC and SCADA system control; in transportation, they are used for signal control and monitoring; and in critical infrastructures, such as power and water, they are used for monitoring and management.

Similarities between industrial PCs and commercial PCs

Information reception, storage and processing capabilities:

Industrial PCs and commercial PCs are similar in their basic information processing capabilities; both are capable of receiving, storing, and processing data to perform tasks based on software instructions.

Similarity in hardware components:

Industrial PCs and commercial PCs share similarities in hardware components, including motherboards, CPUs, RAM, expansion slots, and storage devices, but the components used in industrial PCs are typically more durable and reliable.

Choosing the right tool

Choose a PC for specific applications:

Standard PCs are suitable for general tasks and everyday use, such as document processing, Internet browsing, etc.Industrial PCs for specialised industrial applications that require durability, reliability and resistance to harsh conditions: Industrial PCs are designed for stable operation in extreme environments and are suitable for specialised applications such as industrial automation and production control.

Understand these differences to optimise performance and longevity in specific applications:

Understand the different characteristics of industrial PCs and standard PCs, and choose the device that best suits the needs of a specific application to ensure the best performance and longest life of your system.

Maintenance and Lifecycle Management

Maintenance practices for industrial PCs vs. personal computers:

Industrial PCs typically have low maintenance requirements, but require specialised personnel to repair them in the event of a failure. PCs, on the other hand, are relatively simple to maintain and can be left to the user to deal with common problems.

Lifecycle management and total cost of ownership:

Industrial computers have a high initial investment, but a low total cost of ownership due to their high reliability and long lifespan. Personal computers have a low initial cost, but frequent upgrades and maintenance may increase the total cost of ownership.

Future Trends and Developments

Emerging technologies and trends in industrial controllers:

with the development of Industry 4.0 and IoT, industrial controllers will integrate more intelligent and networked functions, such as edge computing and AI algorithm support.

Development of personal computers and their potential overlap with IPC functions:

personal computers continue to improve in terms of performance and versatility, and some high-end PCs may be able to replace the functions of lower-end industrial controllers under certain conditions, with possible overlap of functions in the future.

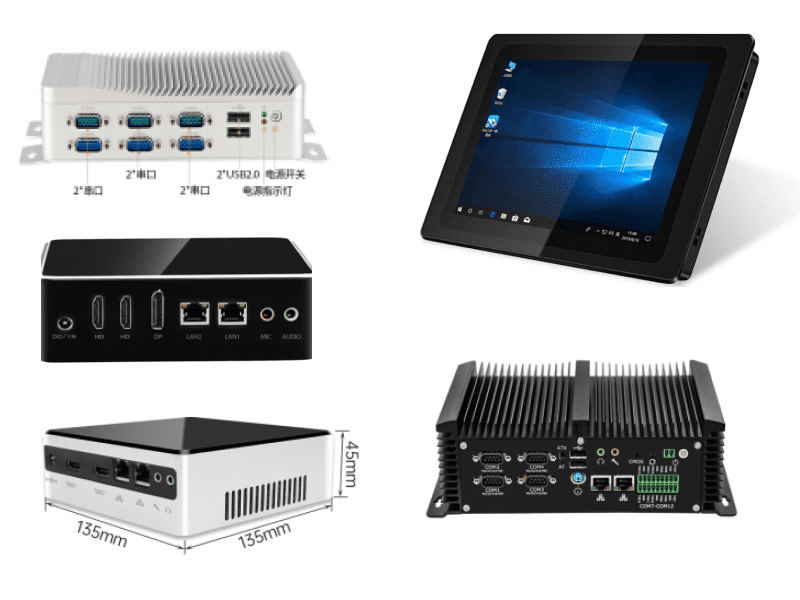

COMPT is a China-based industrial PC manufacturer with more than 10 years of experience in custom development and production. We provide customised solutions and cost-effective industrial Panel PCs, industrial monitors, mini PCs and rugged tablet PCs to our global customers, which are widely used in industrial control sites, automated smart manufacturing, smart agriculture, smart cities and smart transportation. Our markets include 50% of the EU market, 30% of the US market and 30% of the Chinese market. We offer full-size PCs and monitors from 7” to 23.8” with a variety of customised interfaces to suit all customer application scenarios. I have the expertise to guide you through the selection and use of the right industrial PC, including the various types of interfaces, sizes and installation methods. In my ten years of experience in the industry, I know that choosing the right industrial PC is critical to your organisation’s productivity and equipment reliability. Industrial PCs differ significantly from personal PCs in design, performance and application. Understanding these differences and choosing the right product for your needs can greatly improve productivity, reduce maintenance costs, and ensure stable system operation in harsh environments. If you have any needs or questions about industrial PCs, please feel free to contact us and we will be happy to provide you with the best quality solutions.

Media Contact

Company Name: Guangdong Computer Intelligent Display Co., Ltd.

Email: Send Email

Country: China

Website: https://www.gdcompt.com/